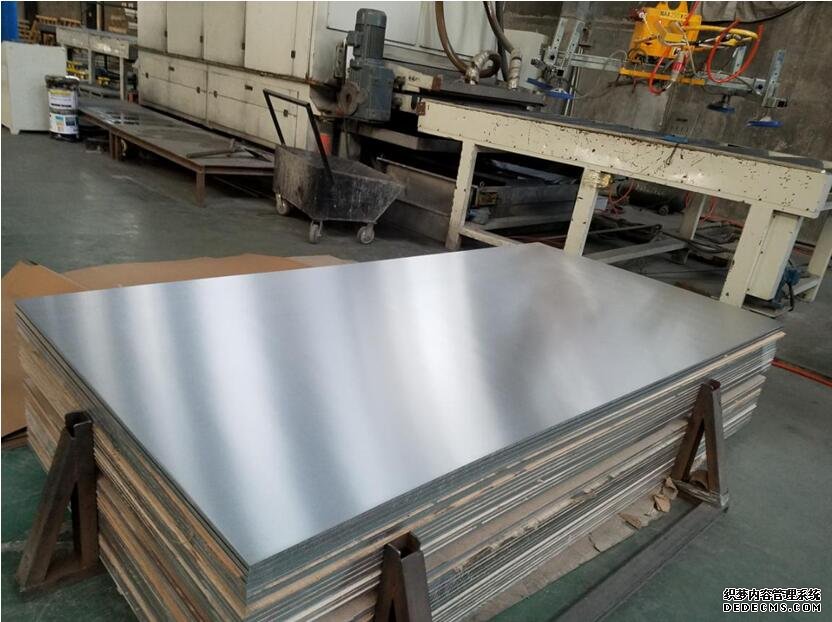

Aircraft aluminum sheet are a kind of ultra-high-strength deformed aluminum sheet, which is currently widely used in the aviation industry. It has better mechanical and processing properties, good plasticity after solution treatment, and good heat treatment strengthening effect. Generally, it has high strength below 150°C (or even higher), and has good fit. It is an ideal structural material.

The ratio of

aircraft aluminum sheet to ordinary aluminum sheet has higher requirements for strength, hardness, index, fatigue resistance, and plastics. Due to its light weight and significant lightweight effect, aviation aluminum has replaced steel and replaced the current aviation materials. Aviation equipment has high requirements for aluminum, which is an important high-end application market for aluminum.

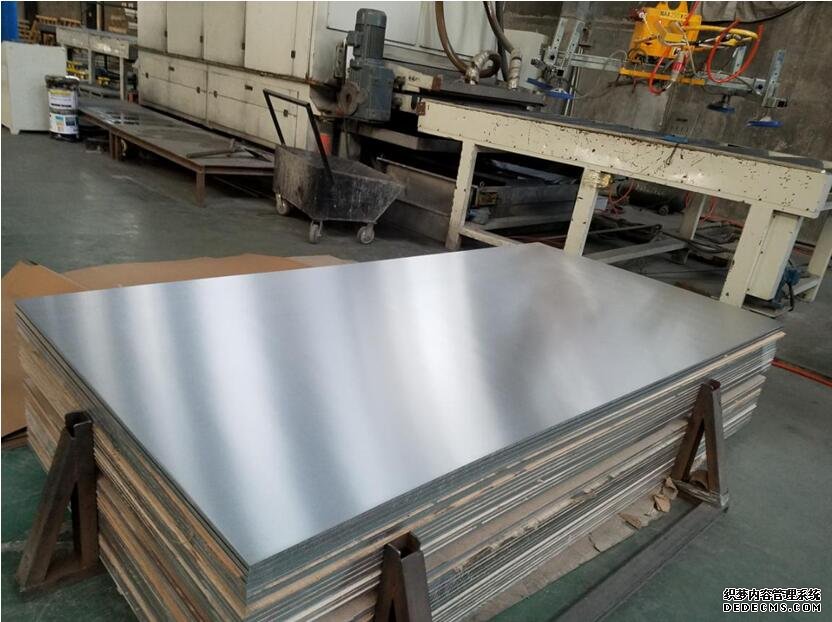

In today’s world,

aircraft aluminum sheets are mainly high-strength 2 series (2024, 2017, 2A12, etc.) and ultra-high-strength 7 series (7075, 7475, 7050, 7A04, etc.), and some 5 series (5A06, 5052, etc.) 5086, etc.) and 6 series (6061, 6082, etc.) and a small amount of other series of aluminum.

Aircraft aluminum sheets are mainly used in wing surface skins, wing surface girders, upper and lower edge strips of wing spars, webs, fuselage girders, seat slides, keel beams, side frames, fuselage skins, and lower fuselage walls Plates, main floor stringers, etc.

1. Duralumin: aluminum-magnesium-copper alloy. The most widely used aluminum sheet in the aviation industry. Commonly used 2024, 2A12, 2017A, strength, toughness, fatigue resistance, good plasticity. Used to make skins, bulkheads, wing ribs, etc.

2. Super hard aluminum: aluminum-zinc-magnesium-copper alloy. Commonly used 7075, 7A09, the ultimate strength and yield strength, high load, used to make the upper wing surface skin, beams, etc.

3. Anti-rust aluminum plate: commonly used aluminum-magnesium alloy 5A02, 5A06, 5B05. It has high corrosion resistance, fatigue resistance, good plasticity and weldability. Used to make mailboxes, oil pipes, etc.

4. Forged aluminum plate, commonly used 6A02, has high hardness and good corrosion resistance. Manufacturing engine parts, joints, etc.

5. Cast aluminum plate, low specific gravity, high corrosion resistance and heat resistance, making engine casings, etc.