As a mature light-weight high-strength alloy material, aluminum alloy is widely used in aerospace. Aluminum alloy material is generally used as structural material, which has higher specific strength and better processing properties than steel. In the aerospace field, aluminum alloy materials with high strength, high toughness and strong corrosion resistance are mainly developed to meet the severe service conditions of aerospace. 2000 series and 7000 series aluminum alloys are mostly used. On the basis of high-strength aluminum alloys, the process and material formula are improved, and light aluminum alloy materials with better performance are developed through innovative production processes such as powder metallurgy and spray molding, Carry out research on aluminum matrix composites and superplastic aluminum alloy materials. In the development and application of lightweight high-strength aluminum alloy, stress corrosion is the main problem in the whole application and development history of aluminum alloy. How to weaken or delay the stress corrosion of high-strength aluminum alloy in the process of use

Stress corrosion has become the main problem in the application of aluminum alloy.

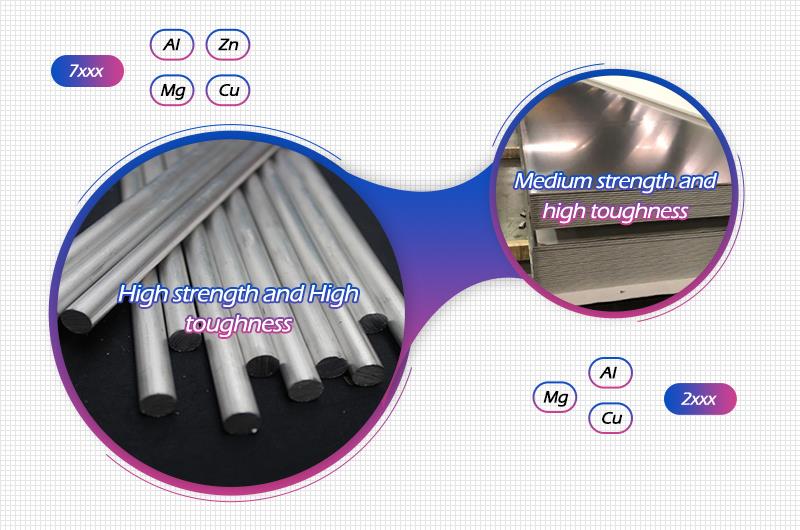

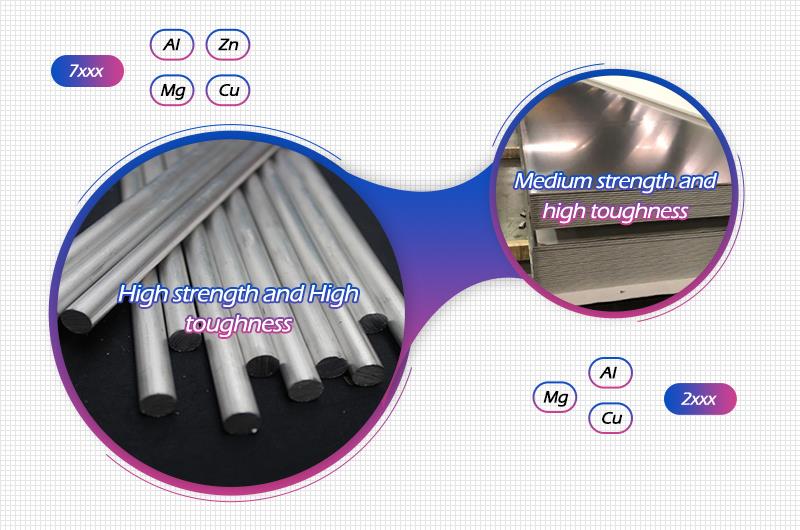

The main components of 2000 series aluminum alloy are mainly aluminum (AL), copper (Cu) and magnesium (mg), the main components of 7000 series aluminum alloy are al, zinc (Zn), Mg and Cu, and some high-performance (high strength, high toughness and corrosion resistance) aluminum alloy materials obtained by adding some special elements. At present, the main way to obtain high-performance aluminum alloy materials is to change the melting and casting conditions. The 2000 series aluminum alloy mainly takes Cu as the main alloy element. The alloy prepared by adding an appropriate amount of Cu into the aluminum alloy material will have better improvement in strength, heat resistance and processing performance, but the corrosion resistance will be reduced, because the introduction of Cu will make the aluminum alloy more prone to intergranular corrosion, and the material constituent elements directly affect the performance of the aluminum alloy. Therefore, the 2000 series aluminum alloy is generally coated with pure aluminum or 6000 series aluminum alloy as the electrochemical protective film of the body aluminum alloy to improve its corrosion resistance. Later, scholars conducted a lot of research on the methods of improving the stress corrosion performance of different grades of aluminum alloys, which delayed the degree of stress corrosion of aluminum alloys to a certain extent. Aluminum alloy material is an important component material to ensure the safe flight of aircraft. The selection and performance prediction of aluminum alloy materials in different parts are directly related to the safety and reliability of aircraft. Predicting the failure of aviation aluminum alloy materials is directly related to life safety, which needs to be paid extensive attention.

High strength aluminum alloys with excellent performance are mainly used in aerospace and military fields, because aerospace and military products have high requirements for weight reduction. Materials with high specific strength are the preferred materials for aerospace. Among aluminum materials for aircraft, 7000 series high strength and high toughness aluminum alloys and 2000 series medium strength and high toughness aluminum alloys play an important role.