In the field of aerospace, the first application of aluminum alloy can be traced back to more than 100 years ago. In 1903, the Wright brothers of the United States invented the "flyer" aircraft. At that time, aluminum was one of the components of the engine.

With the continuous upgrading of the performance of aluminum alloy and its inherent lightweight advantages, aluminum has gradually replaced wood and steel as the main material on the aircraft. In particular, the demand for high mobility bombers and fighters in the Second World War further promoted the application of aluminum. High strength and toughness 2 represented by 2024, 7075 and other alloys ××× And 7 ××× Series aluminum alloy has become the mainstream of aluminum for aerospace.

According to the composition, Al Li alloy should belong to 2 ××× (Al-Cu)、5 ××× (Al Mg) or 8 ××× It is one of the alloys, but because of its outstanding comprehensive properties, special melting and casting technology and broad application prospects, it has gradually become the same as 2 ×××、 seven ××× It is a new generation of high-performance aluminum alloy.

Aluminum lithium alloys

Aluminum lithium alloys is expected to become the most promising aluminum for aerospace in the next generation. Its advantages are mainly reflected in: (1) the density is lower than that of traditional aluminum alloy. Lithium is the lightest metal. Every 1% lithium added to aluminum can reduce the overall density of the material by 3%;

2) The comprehensive performance is better than that of traditional aluminum alloy. Li element can form Al3Li, alxculi, alxmgli and other strengthening phases, which can significantly improve the elastic modulus, strength, corrosion resistance and damage tolerance of the material.

Due to the low density of metal Li (0.534 g / cm3) and the combination of Li elements with Cu and Mg elements to form strengthening phases (Al3Li, Al2CuLi, etc.), ALU Li alloys is in the realization of material

With the decrease of material density (2.7 g / cm3), the specific strength and specific stiffness of materials can be significantly improved, so it has been widely used in the field of aerospace. The main application parts of Al Li alloy include: (1) damage resistant skin sheet, and the main alloy brands involved include 2060-t8e30, 2198-t8, 2199-t8e74, etc;

(2) The main alloy grades involved in the high-strength toughened wing wall panel or internal load-bearing parts include 2050-t84, 2055 - t8x, 2199 - t86, 2060 - t8x, etc; (3) For low-density guide rail or bearing parts, the alloy grades involved include 2196-t8x, 2099-t81, 1420, 2055, etc.

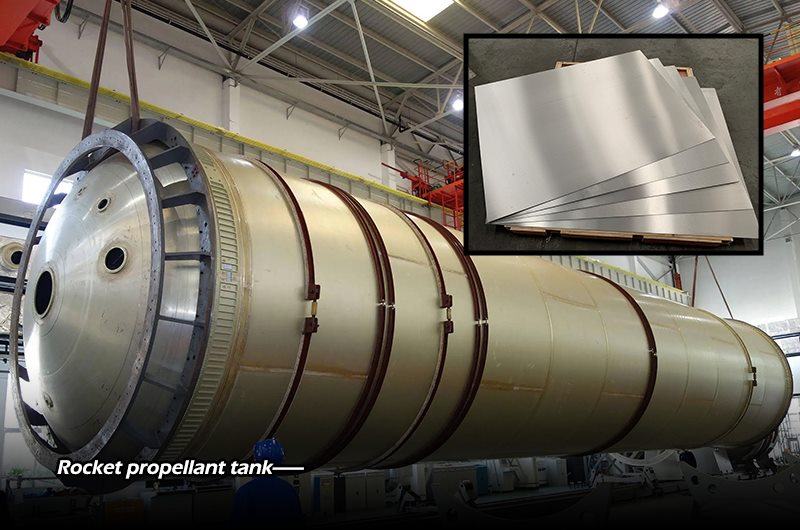

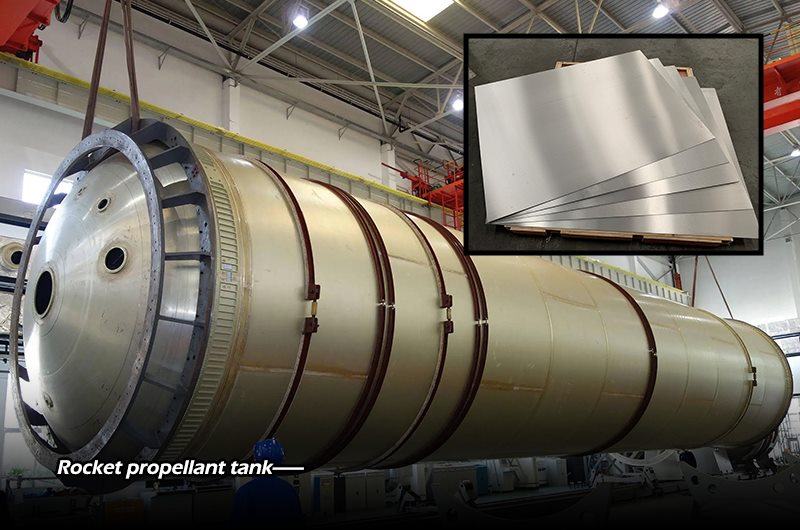

In the aerospace field, based on the requirements of high strength and weldability, aluminum lithium alloys is mainly used in rocket propellant tanks, including liquid hydrogen and liquid oxygen tanks and spinning end caps; High strength is the primary consideration index in spacecraft material selection. At the same time, due to the space shuttle crash in the last century, the stress corrosion resistance assessment of materials is also the key index of Al Li alloy. The most widely used alloy grades are 2195-t8x, 2055-t84, 2098-t8x, 2099, etc. the density of this kind of alloy is generally between 2.6 ~ 2.7 g / cm3, the material strength reaches 600 MPa or higher, the compressive modulus is 75 ~ 79 GPA, and the specific stiffness is between 26 ~ 30 GPA ⋅ cm3 / G.

Since the first Li containing aluminum alloy scleron came out in 1924, the research and development history of aluminum lithium alloy will be a hundred years. The early development of

Al Li alloy was driven by the lightweight demand of aviation industry, which depended on its characteristics of low density and high specific strength. In recent years, with the continuous progress of technology, people increasingly find that lightweight is not the only advantage of Al Li alloy. In terms of damage resistance, fatigue life and corrosion resistance,

Aluminum lithium alloys are comparable to traditional 2 ×××、 seven ××× Trend of aluminum alloys.

Future research and development directions of

aluminum lithium alloys may include:

(1) Fully tap the comprehensive performance advantages of Al Li alloy in addition to low density and high specific strength, carry out technical research and industrial application in the direction of material damage resistance, fatigue life and corrosion resistance, develop the fourth generation of Al Li alloy, and further expand the application of Al Li alloy in aerospace, marine ships and other directions.

(2) Continue to promote the comprehensive performance optimization of the third generation aluminum lithium alloy and partially replace 2 ××× And 7 ××× It is a high-performance aluminum alloy, which can achieve the development goal of improving comprehensive properties by 20% while ensuring low density. For example, in the field of high-strength aluminum alloy, 2065, 2055 and 2050 replace 7150, 7055, 7050 and 7175, and t8x heat treatment replaces t7x heat treatment; In the field of medium strength damage resistant aluminum alloy, 2076, 2060 and 2099 replace 2024, 2624 and 2324, and t8x heat treatment replaces T3x heat treatment.

(3) Research and develop low-cost aluminum lithium alloy preparation technology. Accelerate the research and development of new generation melting and casting technology, spray forming technology and powder metallurgy technology, and improve the alloy yield in the production of raw materials; The research and development of Ag free Al Li alloy has further reduced the comprehensive cost of Al Li alloy.