E-mail:

sales@chalcoaluminum.com

E-mail:

sales@chalcoaluminum.com

Email: sales@chalcoaluminum.com

Mobile:86 17344894490

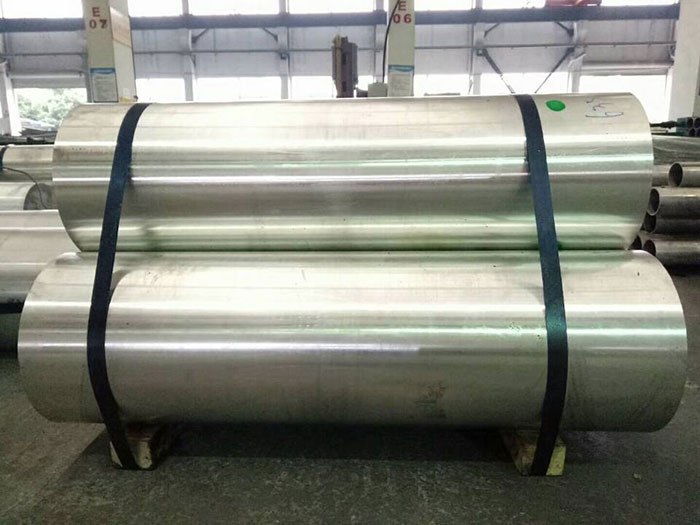

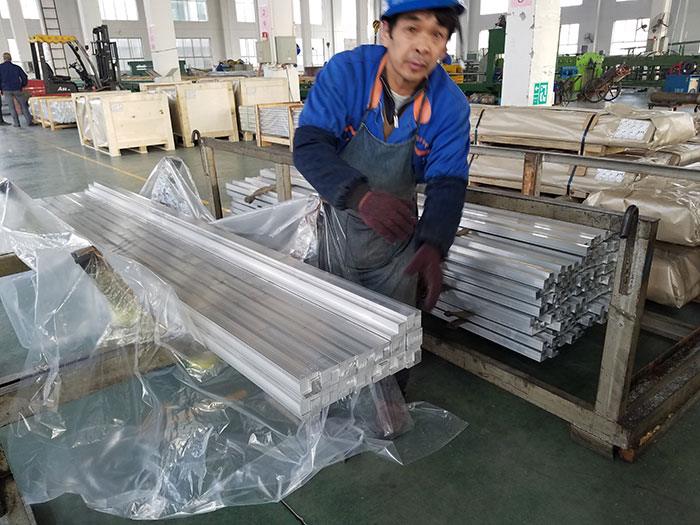

2014 Aircraft aerospace aluminum profile forgings

| Chemical Composition of 2014 alloy | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Others | Al | |

| Each | Total | ||||||||||||

| 2014 | 0.50~1.2 | 0.70 | 3.9~5.0 | 0.4~1.2 | 0.2~0.8 | 0.10 | ~ | 0.25 | 0.15 | ~ | 0.05 | 0.15 | Remainder |

| Alloy | Alloy series | Main features | Σb Value /MPa | Working Temperature /℃ |

| 2014 | Al-Cu-Mg | Heat treatment of reinforced alloys, the main varieties are rod and forgings. It has good thermal processing performance and is suitable for the manufacture of complex free forgings and die forgings. |

435~455 |

<175 |

| Parameters of 2024 aluminum alloy | ||||||||

| Alloy | Type | Temper | δ or d/mm | σb/MPa | σp 0.2/MPa | δ/% | KIC or KC/MPa | Technical standard |

| 2014 | Extruded aluminum bar | T6 | ≤75 | 490 | 440 | 7 | - |

Z9-0409-1992 Q/EL 336-1992 |

| >75~100 | 480 | 435 | 7 | - | ||||

| T4 | ≤75 | 410 | 270 | 12 | - | |||

| >75~100 | 400 | 260 | 12 | - | ||||

| Die forgings | T6 |

L:450 LT:440 |

L:380 LT:380 |

L:7 LT:3 |

- | Q/S 819-1992 | ||

| Typical application of aluminum alloy 2014 | ||||

| Alloy | Features | Type | Aircraft model | Application parts and typical parts |

| 2014 |

It has high strength, forging performance, heat resistance and weldability. It is an important material used in aerospace industry and rubber mold manufacturing industry. After annealing, quenching, aging and other heat treatment, all kinds of excellent properties of the alloy sheet can be obtained. |

Forgings:T6 Cold working aluminum bar:T4、T6 |

ARJ21,Z9 etc | Window frame |