E-mail:

sales@chalcoaluminum.com

E-mail:

sales@chalcoaluminum.com

Email: sales@chalcoaluminum.com

Mobile:86 17344894490

2B16 Aircraft aerospace aluminum wire rod

| Chemical Property of 2B16 Alloy | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Others | Al | |

| Unit | Total | ||||||||||||

| 2B16 | 0.25 | 0.30 | 5.8~6.8 | 0.2~0.4 | 0.05 | - | - | - | 0.08~0.2 | 0.10~0.25 | 0.05 | 0.15 | Remainder |

| Alloy | Alloy Series | Main features |

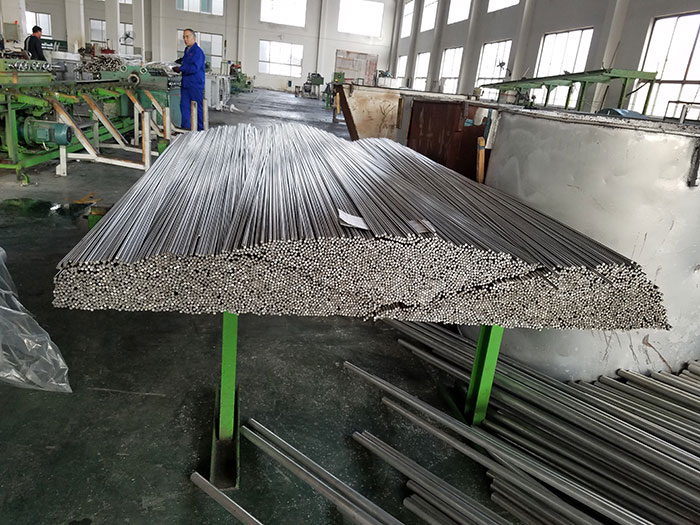

| 2B16 | Al-Cu-Mn | The heat treatment strengthened alloy, Al-Cu-Mn rivet alloy, is used for riveting the aeronautical spacecraft. It has good riveting performance, and it can work for a long time below 250 degrees. Its room temperature and high temperature shear strength is higher than that of 2A10 alloy. It can be used for a long time after heat treatment. The supplied wire is 1.6~10mm in diameter and is delivered in a cold hardened state. The rivets are used to riveting heat resistant structures of large missiles, large launch vehicles and aircraft after solid solution treatment and artificial aging. |

| Shear strength of 2B16-T6 alloy wire after heating for 30min at 200 ℃ | |||

| Standard | Test Condition | d/mm | Tm/(Mpa) Not less than |

| GJB 2055 | Solid solution heat treatment at 535 ℃ + artificial aging 175℃, 12h | All | 275 |

| Q/6S 113 | Solid solution heat treatment at 525℃ + artificial aging 165℃, 12h | 4 | 275 |

| 6 | 265 | ||

| Calibrated shear strength of alloy wire of 2B16-T6 | |||

| Standard | Test Condition | Grade | Tm/(Mpa) Not less than |

| GJB 2055 | Solid solution heat treatment at 535 ℃ + artificial aging 175 ℃, 12h | A | 186 |

| B | 177 | ||

| Typical room temperature shear strength of alloy 2B16-T6 | |||||

| Type | Test Condition | d/mm | σb/MPa | σp 0.2/MPa | δ/% |

| Aluminum round bar | Solid solution heat treatment at 525 ℃+ artificial aging 165℃, 12h | All | 403 | 252 | 23.3 |

| Aluminum wire | Solid solution heat treatment at 525 ℃+ artificial aging 200℃, 12h | 4 | 329 | - | - |

| Solid solution heat treatment at 525 ℃+ artificial aging 250℃, 12h | 4 | 275 | - | - | |

| Typical room temperature shear strength of alloy of 2B16 | ||||

| Test Condition | d/mm | Stabilization treatment | Shear strength Tm/(Mpa) | |

| Temperature/℃ | Time/h | |||

| Solid solution heat treatment at 525 ℃ + artificial aging 165 ℃ /12h | 4 | - | - | 290 |

| Solid solution heat treatment 535℃ + cold drawn 1%~3% deformation rate + artificial aging 175 centigrade /18h | - | - | 274 | |

| Solid solution heat treatment at 535 ℃ + artificial aging 190 ℃ /18h | - | - | 263 | |

| Solid solution heat treatment at 525 ℃ + artificial aging 165 ℃ /12h | 125 | 100 | 288 | |

| 150 | 100 | 277 | ||

| 175 | 100 | 240 | ||

| 225 | 100 | 200 | ||

| 250 | 100 | 179 | ||

| 300 | 100 | 163 | ||

| Solid solution heat treatment 535 ℃ + cold drawn 1%~3% deformation rate + artificial aging 175 ℃ /18h | 200 | 100 | 225 | |

| Solid solution heat treatment at 535 ℃ + artificial aging 190 ℃/18h | 190 | 100 | 228 | |

| 200 | 100 | 222 | ||

| 220 | 100 | 218 | ||

| 250 | 100 | 200 | ||

| Typical room temperature shear strength of alloy of 2B16 | ||||

| Test Condition | d/mm | Stabilization treatment | Shear strength Tm/(Mpa) | |

| Temperature/℃ | Time/h | |||

| Solid solution heat treatment at 525 ℃ + artificial aging 165 ℃ /12h | 4 | - | - | 290 |

| Solid solution heat treatment 535℃ + cold drawn 1%~3% deformation rate + artificial aging 175 centigrade /18h | - | - | 274 | |

| Solid solution heat treatment at 535 ℃ + artificial aging 190 ℃ /18h | - | - | 263 | |

| Solid solution heat treatment at 525 ℃ + artificial aging 165 ℃ /12h | 125 | 100 | 288 | |

| 150 | 100 | 277 | ||

| 175 | 100 | 240 | ||

| 225 | 100 | 200 | ||

| 250 | 100 | 179 | ||

| 300 | 100 | 163 | ||

| Solid solution heat treatment 535 ℃ + cold drawn 1%~3% deformation rate + artificial aging 175 ℃ /18h | 200 | 100 | 225 | |

| Solid solution heat treatment at 535 ℃ + artificial aging 190 ℃/18h | 190 | 100 | 228 | |

| 200 | 100 | 222 | ||

| 220 | 100 | 218 | ||

| 250 | 100 | 200 | ||

| High temperature shear strength of 2B16 alloy | |||||||

| Test Condition | d/mm | Stabilization treatment | Temperature/℃ | Time/h | Shear strength Tm/(Mpa) | ||

| Temperature/℃ | Time/h | ||||||

| Solid solution heat treatment at 525 ℃ + artificial aging 165 ℃ /12h | 4 |

- - - |

- - - |

100 | 30 | 269 | |

| 125 | 247 | ||||||

| 150 | 232 | ||||||

| 175 | 215 | ||||||

| 200 | 198 | ||||||

| 220 | 150 | ||||||

| Solid solution heat treatment 535℃ + cold drawn 1%~3% deformation rate + artificial aging 175 centigrade /18h | 185 | 194 | |||||

| 190 | 189 | ||||||

| 200 | 184 | ||||||

| 210 | 172 | ||||||

| 220 | 156 | ||||||

| Solid solution heat treatment at 535 ℃ + artificial aging 190 ℃ /18h | 185 | 196 | |||||

| 190 | 187 | ||||||

| 200 | 178 | ||||||

| 210 | 169 | ||||||

| 220 | 155 | ||||||

| 250 | 115 | ||||||

| Solid solution heat treatment at 525 ℃ + artificial aging 165 ℃ /12h | 125 |

100 |

125 | 30 | 260 | ||

| 150 | 150 | 236 | |||||

| 175 | 175 | 196 | |||||

| 225 | 225 | 121 | |||||

| 250 | 250 | 90 | |||||

| 300 | 300 | 68 | |||||

| Solid solution heat treatment 535 ℃ + cold drawn 1%~3% deformation rate + artificial aging 175 ℃ /18h | 220 | 220 | 139 | ||||

| Solid solution heat treatment at 535 ℃ + artificial aging 190 ℃/18h | 190 | 190 | 158 | ||||

| 200 | 200 | 148 | |||||

| 220 | 220 | 137 | |||||

| 250 | 250 | 109 | |||||