E-mail:

sales@chalcoaluminum.com

E-mail:

sales@chalcoaluminum.com

Email: sales@chalcoaluminum.com

Mobile:86 17344894490

2618A Aircraft aerospace aluminum bar sheet

| Chemical Composition of 2618A | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Others | Al | |

| Each | Total | ||||||||||||

| 2618A | 0.15~0.25 | 0.9~1.4 | 1.8~2.7 | 0.25 | 1.2~1.8 | ~ | 0.8~1.4 | 0.15 | 0.20 | ~ | 0.05 | 0.15 | Remainder |

| Alloy | Alloy series | Main features | σb Value /MPa | Working temperature /℃ |

| 2618A | Al-Cu-Mg | The machine is similar to 2618 alloy. The alloy has high heat resistance, good cold and heat processing property and moderate welding performance. It is suitable for manufacturing parts used at higher temperature. | 415~470 | <150 |

| Technical indexes of common 2618A aluminum alloy | ||||||||||||||

| Alloy | Type | Temper | δ or d/mm | σb/MPa | σp 0.2/MPa | δ/% | KIC or KC/MPa | Technical standard | ||||||

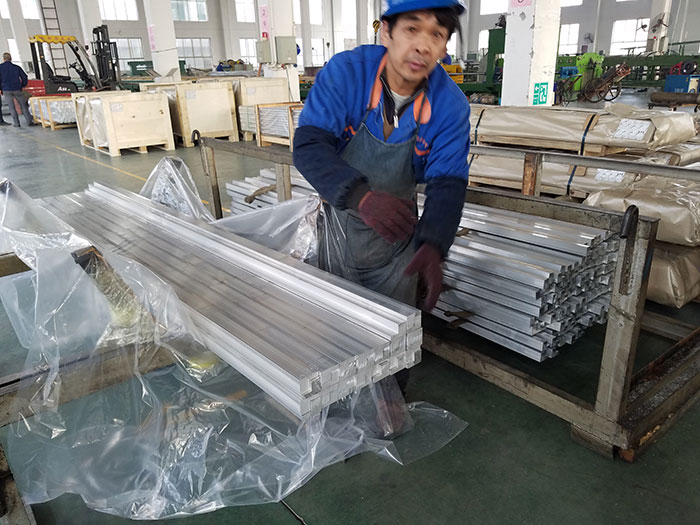

| 2618A |

Aluminum round bar |

T6 | ≤220 | 410 | 340 | 6 | ~ | Z9-0411--1992 | ||||||

| T851 | 10~75 | 434 | 290 | 8 | ~ | |||||||||

| >75 | 410 | 350 | 6 | ~ | ||||||||||

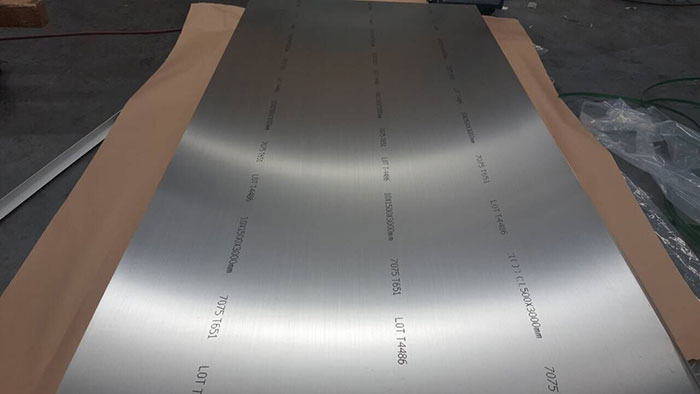

| Aluminum sheet |

T851 |

8~40 | 430 | 385 | 5 | ~ | Z9-0411--1992 | |||||||

| >40~60 | 420 | 385 | 5 | ~ | ||||||||||

| >60~80 | 420 | 380 | 5 | |||||||||||

| >80~90 | 410 | 370 | 4 | ~ | ||||||||||

| 2618A Welding property | ||||||||||||||

| Alloy | Resistance welding | Melting welding | Argon arc welding | Note | ||||||||||

| 2618A | The welding performance is unstable at a specific temperature, but the resistance welding is better. | |||||||||||||

| Alloy | Temper | Aircraft types | Application parts and typical parts |

| 2618A |

Aluminum plate: T851 Cold working aluminum round bar:T6、T851 |

Concorde,Z9 | Aircraft wing skin |