E-mail:

sales@chalcoaluminum.com

E-mail:

sales@chalcoaluminum.com

Email: sales@chalcoaluminum.com

Mobile:86 17344894490

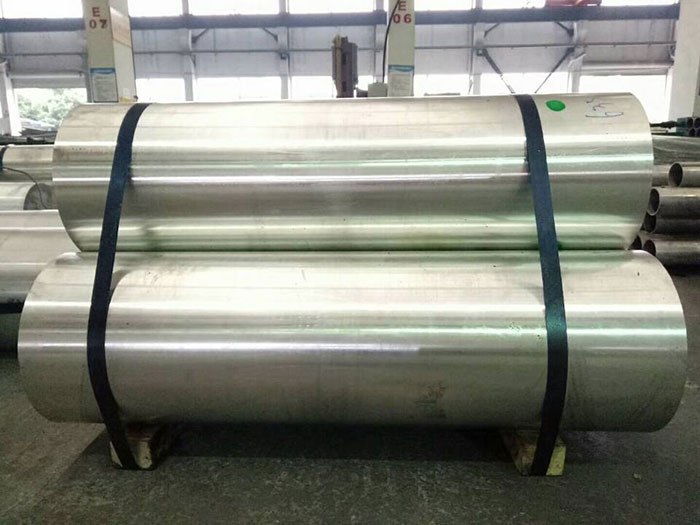

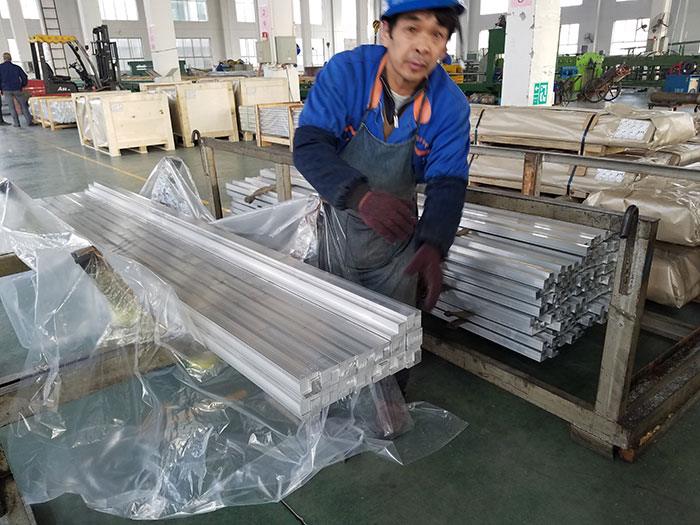

2A50 Aircraft aerospace aluminum bar profile forgings

| Chemical Property of 2A50 | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Others | Al | |

| Each | Total | ||||||||||||

| 2A50 | 0.7~1.2 | 0.70 | 1.8~2.6 | 0.4~0.8 | 0.4~0.8 | - | 0.10 | 0.30 | 0.15 | 0.10~0.25 | 0.05 | 0.15 | Remainder |

| Alloy | Alloy series | Main features |

| 2A50 | Al-Cu-Mn | Heat-treated reinforced alloy, Al-Cu-Mg alloy. It has good plasticity in thermal state and high strength and plasticity in T6 state. It is widely applied to various large, medium and small forgings, such as aircraft frame, joint, bracket, rocker arm and so on, which are used for forging medium aviation industry. The electric arc welding and gas welding alloy contact welding performance is poor, the performance is acceptable, excellent performance of friction stir welding. |

| Demarcation mechanical properties of 2A50 alloy bar | |||||

| Technical standard | Type | Temper | d/mm | Rm /Mpa | A/% |

| Not less than | |||||

| GB/T 3191 | Extruded aluminum bar | T6,T62 | ≤150 | 355 | 12 |

| GJB 2054 | Extruded aluminum bar | T6 | 5~150 | 350 | 12 |

| >150 | 350 | 8 | |||

| HB 5202 | Extruded aluminum bar | T6 | ≤22 | 365 | 12 |

| >23 | 375 | 10 | |||

| 161~240 | 365 | 8 | |||

| GB/T 3191 | High strength aluminum bar | T6, T62 | 20~120 | 380 | 10 |

| GJB 2054 | T6 | 20~150 | 380 | 10 | |

| Demarcation mechanical properties of 2A50 alloy free forgings and die forgings | |||||||||||

| Standard | Type | Temper | L | LT | ST | HBS | |||||

| Rm/Mpa | Rp0.2/Mpa | A5/% | Rm/Mpa | Rp0.2/Mpa | A5/% | Rm/Mpa | A5/% | ||||

| GJB 2351 | Free forgings | T6 | 365 | - | 8.0 | 345 | - | 6.0 | 335 | 4.0 | 95 |

| Die forgings | T6 | 380 | 275 | 10.0 | 365 | 245 | 1.0 | 345 | 5.0 | 100 | |

| HB 5204 | Free forgings | T6 | 365 | - | 9.0 | 345 | - | 6.0 | 335 | 4.0 | 95 |

| Die forgings | T6 | 380 | 275 | 11.0 | 365 | 245 | 7.0 | 345 | 5.0 | 100 | |

| 2A50 T6 Mechanical properties of alloy 110mm forgings after stabilizing treatment | |||

| Stabilizing Condition | Tension strength Rm/Mpa | Elongation A5/% | |

| Temperature/℃ | Time t/h | ||

| 20 | 0.5 | 275 | 15 |

| 100 | 221 | 18 | |

| 200 | 0.5 | 177 | 16 |

| 100 | 98 | 35 | |

| 250 | 0.5 | 177 | 16 |

| 100 | 98 | 35 | |

| 300 | 0.5 | 103 | 23 |

| 100 | 64 | 45 | |

| Fracture toughness of alloy 2A50 T6 | |||

| Type | d/mm | Test Direction | KIC/(N.mm-2)/ |

| Free forgings | LT | 39~42 | |

| TL | 36~39 | ||

| SL | 31~34 | ||

| Aluminum round bar | ≤140 | RL | 31 |