E-mail:

sales@chalcoaluminum.com

E-mail:

sales@chalcoaluminum.com

Email: sales@chalcoaluminum.com

Mobile:86 17344894490

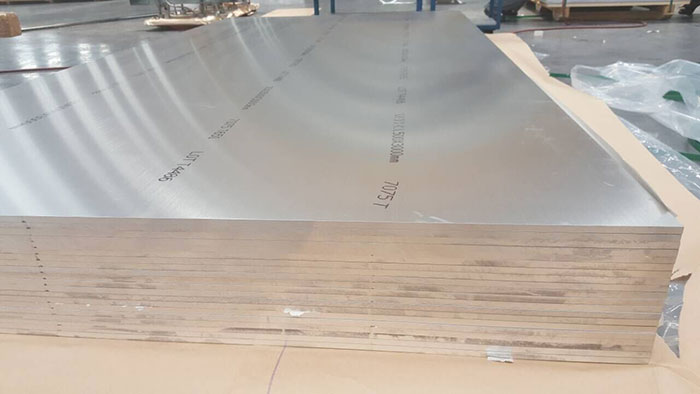

2A11 Aircraft aerospace aluminum plate sheet profile forgings

| Chemical Compostion of 2A11 Aircraft Aerospace Aluminum Alloy sheet profile forgings | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Others | Al | |

| Each | Total | ||||||||||||

| 2A11 | 0.70 | 0.70 | 3.8~4.8 | 0.4~0.8 | 0.4~0.8 | ~ | 0.10 | 0.30 | 0.15 | ~ | 0.05 | 0.15 | Remainder |

| Alloy | Alloy Series | Main Features | Σb Values/MPa | Temperature /℃ |

| 2A11 | Al-Cu-Mg | The alloy can be heat-treated with high strength and medium plasticity after solid solution heat treatment and natural aging. The welding performance of the alloy is better. | 285~400 | <150 |

| Technical indexes of common 2A11 aluminum alloy | ||||||||

| Alloy | Type | Temper | δ or d/mm | σb/MPa | σp 0.2/MPa | δ/% | KIC or KC/MPa | Standard |

| 2A11 | Clad aluminum sheet | O | 0.5~2.9 | ≤225 | 12 | ~ | GB/T 3880 | |

| >2.9 | ≤235 | 12 | ||||||

| T42 | 0.5~2.9 | ≥350 | ≥185 | 15 | ~ | |||

| >2.9 | ≥355 | ≥195 | ||||||

| T3 | 0.5~1.6 | ≥375 | ≥215 | 15 | ~ | |||

| >1.6 | 17 | |||||||

| >2.9 | 15 | |||||||

| T4 | 0.5~2.9 | ≥360 | ≥185 | ~ | ||||

| >2.9 | ≥370 | ≥195 | ||||||

| T42 | >4.5 | ≥355 | ≥195 | 15 | ~ | |||

| >10.0 | ≥370 | ≥215 | 11 | |||||

| T42 | >12.5 | ≥370 | ≥215 | 11 | ~ | |||

| >25.0 | ≥330 | ≥195 | 8 | |||||

| >40.0 | ≥310 | ≥195 | 6 | |||||

| F | >70.0 | ≥285 | ≥195 | 4 | ~ | |||

| 2A11 | Aluminum sheet | O | 0.5~2.5 | ≤225 | - | 12 | ~ | GJB 2053 |

| >2.5 | ≤235 | - | 12 | ~ | ||||

| T4 | 0.5~2.5 | ≥365 | ≥185 | 15 | ~ | |||

| >2.5 | ≥375 | ≥195 | 15 | |||||

| 2A11 | Aluminum plate | O | 7~10 | ≤235 | - | 12 | ~ | GJB 2662 |

| T4 | 7~10 | ≥370 | ≥196 | 5 | ~ | |||

| T4 | 7~10 | ≥355 | ≥186 | 12 | ~ | |||

| >10 | ≥370 | ≥215 | 11 | ~ | ||||

| >25 | ≥335 | ≥196 | 8 | ~ | ||||

| >40 | ≥315 | ≥196 | 6 | ~ | ||||

| >70 | ≥285 | ≥196 | 4 | ~ | ||||

| 2A11 | Aluminum pipe | O | All | ≤245 | - | 10 | ~ | GB/T 4437 |

| T4 | ≤120 | ≥355 | ≥195 | 12 | ~ | |||

| >120 | ≥375 | ≥215 | 10 | |||||

| 2A11 | Extruded pipe(wall thickness 5-35mm) | O | 25~250 | ≤245 | 10 | GJB 2381 | ||

| T4 | 25~120 | ≥350 | ≥196 | 12 | ||||

| 120~250 | ≥370 | ≥215 | 10 | |||||

| 2A11 | Extruded round bar | T4 | ≤160 | ≥375 | ≥215 | 12 | GB/T 3191 | |

| >160 | ≥355 | ≥195 | 10 | |||||

| 2A11 | Extruded round bar | T4 | 5~150 | ≥375 | ≥215 | 12 | ||

| >150 | ≥340 | ≥200 | 8 | |||||

| Extruded round bar | T4 | ≤30 | ≥375 | ≥215 | 12 | HB 5202 | ||

| 31~165 | ≥390 | ≥235 | 10 | |||||

| 161~240 | ≥375 | ≥215 | 10 | |||||

| 2A11 | High Strength Extruded round ba | T4 | 23~240 | ≥420 | ≥275 | 9 | HB 5202 | |

| 2A11 | Extruded aluminum profile | O | All | ≤245 | 9 | GJB 2507 | ||

| T4 | ≤10.0 | ≥355 | ≥215 | 12 | ||||

| >10.0 | ≥375 | ≥225 | 12 | |||||

| >20.0 | ≥400 | ≥245 | 12 | |||||

| 2A11 Mechanical properties of alloy cold drawn pipes | ||||||||

| Alloy | Type | Temper | Pipe Size /mm | σb/MPa | σp 0.2/MPa | δ/% | Technical Standard | |

| OD d | Wall thickness δ | |||||||

|

2A11 |

Cold drawn Pipes | F | 所有尺寸 | ≤245 | - | 10 | GJB 2379-1995 | |

| T4 | <22 | ≤1 | ≥375 | ≥195 | 13 | |||

| 1.5~2.0 | 14 | |||||||

| 22~50 | ≤1 | ≥390 | ≥225 | 12 | ||||

| 1.5~5.0 | 13 | |||||||

| >50 | ≤5.0 | ≥390 | ≥225 | 11 | ||||

| Pipes | ≥390 | ≥225 | 12 | |||||

| 2A11 T4 Mechanical properties of aluminum alloy forgings and die forgings | |||||||||||

| Alloy | Type | L | LT | ST | HBS | Technical Standard | |||||

| σb/MPa | σp 0.2/MPa | δ/% | σb/MPa | σp 0.2/MPa | δ/% | σb/MPa | δ/% | ||||

| 2A11 | Free forgings | 355 | - | 10 | 335 | - | 5 | 315 | 4 | 95 | GJB 2351 |

| 355 | - | 10 | 335 | - | 5 | 315 | 4 | 95 | |||

| 375 | - | 11 | 335 | - | 5 | 315 | 4 | 95 | HB 5204 | ||

| Die Forgings | 375 | 195 | 12 | 355 | 175 | 6 | 325 | 5 | 95 | GJB 2351 | |

| 375 | 196 | 12 | 355 | 177 | 6 | 325 | 5 | 95 | |||

| 390 | 205 | 13 | 355 | 175 | 6 | 325 | 5 | 95 | HB 5204 | ||

| Blade die forgings | 355 | - | 13 | - | - | - | - | - | 95 | GJB 2380 | |

| 2024 Wedding Property | ||||

| Alloy | Resistance welding | Melting welding | Argon arc welding | Note |

| 2A11 | Good | Worse | Worse | For gas welding and argon arc welding of aluminum alloy as solder, tend to form crystalline cracks; 4A01 alloy solder, forming cracks tend to be significantly reduced, but the strength of welded joint is greatly reduced, such as heat treatment after welding, the joint strength is close to the substrate, but the ductility decreases. |

| Alloy | Temper | Application model | Application parts and typical parts |

| 2A11 |

Sheet: O、T3、T4、T42、F Plate: O、T4 Cold drawn tube:O、T3 Extruded tube,profile:O、T4 Tube:F、T4 Forgings: T4 |

Y8 | Front of the fuselage |