E-mail:

sales@chalcoaluminum.com

E-mail:

sales@chalcoaluminum.com

Email: sales@chalcoaluminum.com

Mobile:86 17344894490

2A14 Aircraft aerospace aluminum plate sheet bar forgings

| 2A14 Chemical Property | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Others | Al | |

| Each | Total | ||||||||||||

| 2A14 | 0.50-1.2 | 0.70 | 3.9~5.0 | 0.4~1.2 | 0.2~0..8 | 0.10 | ~ | 0.25 | 0.15 | ~ | 0.05 | 0.15 | Remainder |

| Alloy | Alloy series | Main features | Σb Value /MPa | Temperature/℃ |

| 2A14 | Al-Cu-Mg | It's close to 2014. The main varieties are bars, profiles, forgings and plates, etc. It is suitable for high load parts with thick section. The welding performance of the alloy is good, and it does not show brittleness at the cold temperature. It can be used to make the welding parts under the cold working condition. |

375~460 |

<150 |

| Technical indexes of common 2A14 aluminum alloy | ||||||||

| Alloy | Type | Temper | δor d/mm | σb/MPa | σp 0.2/MPa | δ/% | KIC or KC/MPa | Technical Standard |

| 2A14 | Clad aluminum sheet | O | >0.5~10.0 | ≤245 | - | 10 | - | GB/T 3880--1997 |

| T6 | >0.5~10.0 | 430 | 340 | 5 | - | |||

| T62 | >4.5~12.5 | |||||||

| >12.5~40.0 | ||||||||

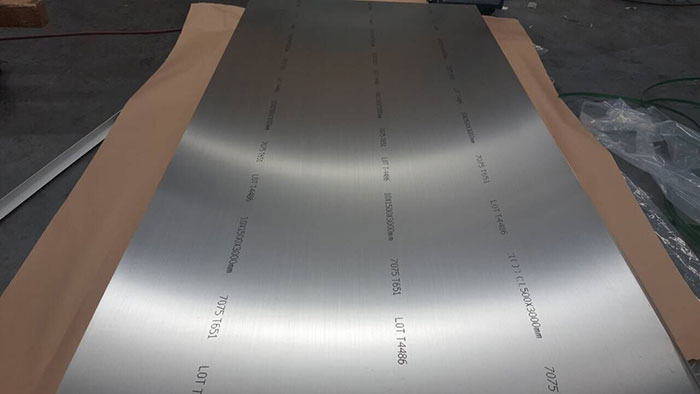

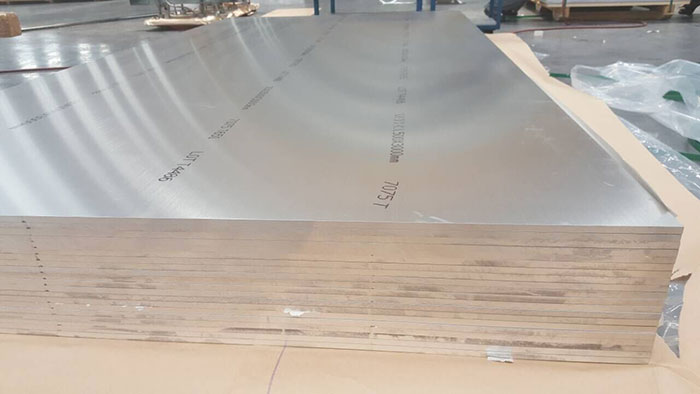

| pre-stretched aluminum plate | T651 | 6.5~12.0 | 460 | 405 | 7 | - | GJB 1741--1997 | |

| >12.0~25.0 | 460 | 405 | 5 | - | ||||

| Aluminum round bar | T62,T6 | ≤22 | 440 | - | 10 | - | GB/T 3191--1998 | |

| >22~150 | 450 | - | 10 | |||||

| High Strength Aluminum bar | T62,T6 | 20~120 | 460 | - | 8 | - | ||

| Extruded aluminum bar | T4,T6 | ≤22 | 440 | - | 10 | - | HB 5202--1982 | |

| 23---160 | 450 | - | 10 | |||||

| 161--240 | 430 | - | 8 | - | ||||

| 2A14 | Extrusion aluminum profile | T4 | All thickness | 375 | 205 | 10 | - | GJB 2507--1995 |

| T6 | ≤10 | 410 | 365 | 7.0 | ||||

| >10 | 450 | 375 | 7.0 | - | ||||

| O | All thickness | 195--275 | - | - | - | |||

| Free forgings | T4 | Weight≤750KG |

L:380 LT:365 ST:325 |

L:245 |

L:10 LT:8 ST:4 |

- | GJB 2351-1995 | |

| Weight>750KG |

L:375 LT:355 ST:325 |

L:235 |

L:8 LT:7 ST:4 |

- | ||||

| Die forgings | T4 | - |

L:380 LT:365 ST:345 |

L:245 LT:235 |

L:11 LT:8 ST:6 |

- | GJB 2351--1995 | |

| Free forgings | T6 | ≤30 |

L:410 LT:355 ST:335 |

- |

L:6 LT:4 ST:2 |

- | ||

| >30 |

L:380 LT:355 ST:335 |

- |

L:6 LT:4 ST:2 |

- | ||||

| Die forgings | ≤30 |

L:430 LT:390 ST:355 |

L:315 |

L:10 LT:6 ST:4 |

- | |||

| >30 |

L:410 LT:390 ST:355 |

L:295 |

L:8 LT:6 ST:3 |

- | ||||

| 2A14 Welding performance | ||||

| Alloy | Resistance welding | Melting welding | Argon arc welding | Note |

| 2A14 | Good | Ok | - | During welding, the tendency of heat crack is larger, so it is necessary to limit the content of iron impurities in the matrix, and the qualified filler can be obtained by using special filler. |

| Alloy | Temper | Model | Application parts and typical parts |

| 2A14 |

Aluminum sheet: O、T6、T62 Aluminum plate: T651 Aluminum round bar:T62、T6 Aluminum Cold working bar:O、T4、T6 Free forgings: T4、T6 |

ARJ21,Z9 | Window Frame |