E-mail:

sales@chalcoaluminum.com

E-mail:

sales@chalcoaluminum.com

Email: sales@chalcoaluminum.com

Mobile:86 17344894490

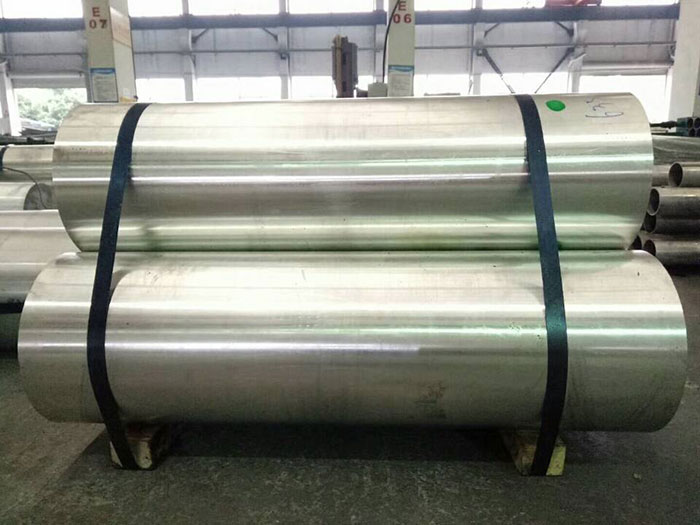

2A02 Aircraft aerospace aluminum bar forgings

| Chemical Composition of 2A02 Aircraft Aerospace Aluminum Bar Forgings | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Other | Al | |

| Single | Total | ||||||||||||

| 2A02 | 0.30 | 0.30 | 2.6~3.2 | 0.45~0.7 | 2.0~2.4 | - | - | 0.10 | 0.15 | - | 0.05 | 0.15 | allowance |

| Alloy | Alloy Series | Main Features |

| 2A02 | Al-Cu-Mn | The heat treatment strengthened alloy, Al-Cu-Mg system, has high strength and plasticity, high heat resistance and corrosion resistance in artificial aging. It is used to manufacture aero turbojet axial compressor blades and other parts at 200 --300℃. |

| Technical Standard | Type | D/mm | Temper | Direction | Rm/Mpa | Rp0.2/Mpa | A/% | HBS |

| Not less than | ||||||||

| GB/T 3191 | Extruded aluminum bar | All Diameters | T6 | L | 430 | 275 | 10 | - |

|

GJB 2054 HB 5202 |

Extruded aluminum bar | ≤240 | T6 | L | 430 | 275 | 10 | - |

|

GJB 2351 HB 5204 |

Forgings | Follow the contract | T6 | L | 390 | 255 | 10 | 100 |

| Mechanical Properties of 2A02 T6 Alloy Extruded Strip (30 x 130mm) at Different Temperatures | |||||

| Temperatures/℃ | Rm/Mpa | Rp0.01/Mpa | Rp0.2/Mpa | A10/% | Z/% |

| 20 | 491 | 274 | 325 | 13.0 | 21.2 |

| 100 | 471 | 247 | 288 | 15.6 | 22.8 |

| 150 | 428 | 268 | 296 | 16.1 | 28.7 |

| 200 | 374 | 228 | 274 | 16.1 | 33.4 |

| 250 | 236 | 128 | 168 | 16.9 | 66.6 |

| 300 | 171 | 94 | 112 | 21.5 | 75.9 |

| 350 | 108 | 25 | 59 | 27.6 | 85.6 |

| Typical Mechanical Properties of 2A06 T6 Alloy Bar at Room Temperature | |||||||||

| Specs d/mm | Rm/Mpa | Rp0.2/Mpa | A10/% | ||||||

| Min. | Max. | Average | Min. | Max. | Average | Min. | Max. | Average | |

| 31 | 500 | 545 | 514.5 | 305 | 430 | 360.2 | 10 | 20 | 15.3 |

| 33 | 500 | 570 | 525.3 | 335 | 440 | 366.3 | 11 | 18 | 15.1 |

| 36 | 495 | 555 | 522.4 | 335 | 380 | 358.4 | 11 | 20 | 15.5 |

| Typical Mechanical Properties of 2A02 T6 Alloy strip and Die Forgings at Room Temperature | |||||

| Type | Specs/mm | Direction | Rm/Mpa | Rp02/Mpa | A10/% |

| Extruded strip | Shape 60×110 | L | 510 | 338 | 17.5 |

| LT | 436 | 294 | 17 | ||

| ST | 436 | 294 | 11.5 | ||

| Forgings | Compressor blade | L | 412~441 | - | 10 |