E-mail:

sales@chalcoaluminum.com

E-mail:

sales@chalcoaluminum.com

Email: sales@chalcoaluminum.com

Mobile:86 17344894490

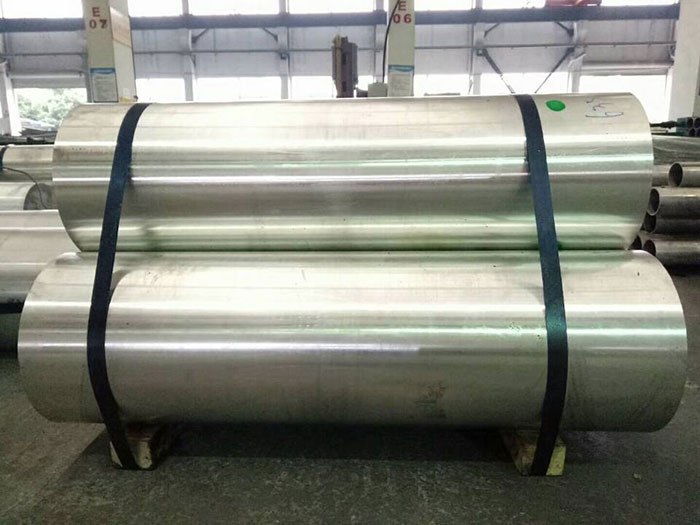

2B50 Aircraft aerospace aluminum bar forgings

| Chemical Composition of 2B50 | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Others | Al | |

| Each | Total | ||||||||||||

| 2B50 | 0.7~1.2 | 0.70 | 1.8~2.6 | 0.4~0.8 | 0.4~0.8 | 0.01~0.20 | 0.10 | 0.30 | 0.02~0.10 | - | 0.05 | 0.15 | Remainder |

| Alloy | Alloy series | Mean features |

| 2B50 | Al-Cu-Mn | The alloy is heat-treated with heat treatment, and the Al-Cu-Mg-Si is a heat treated aluminum alloy. The chemical composition of the alloy is equal to that of 2A50, and the properties of all kinds are basically the same. It has high plasticity in hot state, forging and forging temperature at 420~470 ℃. The alloy is used to make jet engine complex forging parts, such as compressor impeller, impeller and impeller. |

| Alloy | Alloy series | Mean features |

| 2B50 | Al-Cu-Mn | The alloy is heat-treated with heat treatment, and the Al-Cu-Mg-Si is a heat treated aluminum alloy. The chemical composition of the alloy is equal to that of 2A50, and the properties of all kinds are basically the same. It has high plasticity in hot state, forging and forging temperature at 420~470 ℃. The alloy is used to make jet engine complex forging parts, such as compressor impeller, impeller and impeller. |

| Technical standard | d/mm | Rm /Mpa | A5/% |

| Not less than | |||

| HB 5202 | ≤22 | 365 | 12 |

| 23~160 | 375 | 10 | |

| 161~240 | 365 | 8 | |

| Technical Standard | Type | L | LT | ST | HBS | |||||

| Rm/Mpa | Rp0.2/Mpa | A5/% | Rm/Mpa | Rp0.2/Mpa | A5/% | Rm/Mpa | A5/% | |||

| GJB 2351 | Free forgings | 365 | - | 8.0 | 345 | - | 6.0 | 335 | 4.0 | 95 |

| Die forgings | 380 | 275 | 10.0 | 365 | 245 | 7.0 | 345 | 5.0 | 100 | |

| HB 5204 | Free forgings | 365 | - | 9.0 | 345 | - | 6.0 | 335 | 4.0 | 95 |

| Die forgings | 380 | 275 | 11.0 | 365 | 245 | 7.0 | 345 | 5.0 | 100 | |

| Typical room temperature mechanical properties of aluminum alloy impeller die forgings of 2B50 T6 | |||||

| Test Direction | Tension strength Rm9(Mpa) | Yield strength RP0.2(Mpa) | A/% | ||

| Minimum | Maximum | Minimum | Maximum | ||

| L(longitudinal) | 380 | 470 | 280 | 390 | 17.1 |

| LT(Long transverse) | 380 | 465 | 275 | 380 | 15.3 |

| ST(Short transverse) | 385 | 450 | 280 | 370 | 13.7 |