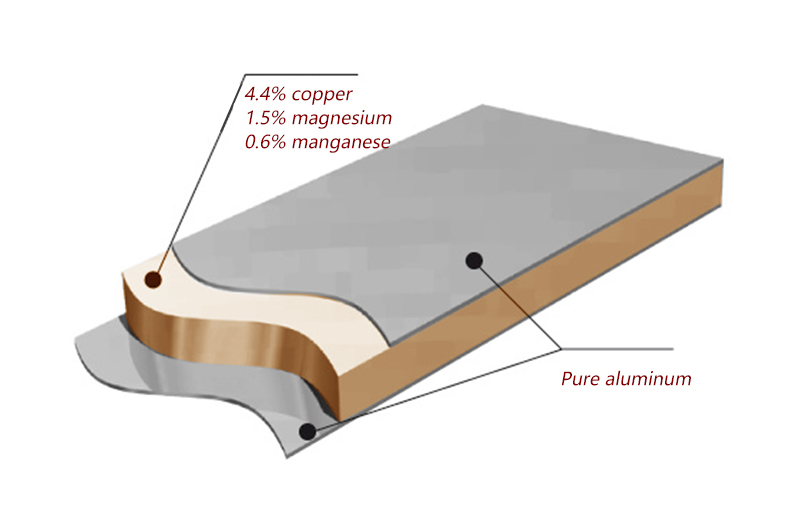

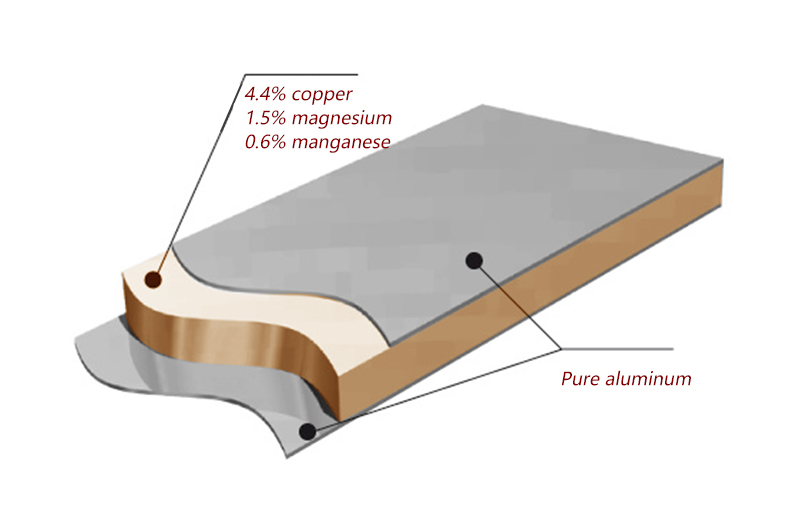

Copper is added to clad aluminum alloy sheets, which not only improves the strength, but also makes the alloy easy to be corroded. Adding a layer of high-purity aluminum plate on the surface will greatly improve the corrosion resistance, which is commonly used in the aviation industry.

Clad aluminum alloy sheets

Clad aluminum alloy sheets is the earliest hardened aluminum alloy. The main alloy elements are copper, manganese and magnesium.

The commonly used alloy type now is AA2024, including (weight percentage) 4.4% copper, 1.5% magnesium and 0.6% manganese. The typical tensile strength is 450MPa, and the strength difference mainly depends on temperature

Because of its high specific strength, it is a commonly used alloy in aircraft. However, because the main material aluminum will melt at about 660 degrees, other high-temperature resistant alloys, such as titanium alloy, will be used for high-speed spraying.

Clad aluminum alloy sheets was first used on the frame of airship. Its composition and heat treatment method were a secret in wartime. Duralumin quickly spread in the aviation industry in the 1930s, and was introduced into the monomer technology of aircraft manufacturing. Duralumin is also very popular in precision tools, with light weight and strength.