7A85 alloy is an advanced high-strength aluminum alloy material and one of the most important key materials needed by the aviation industry. Due to the large defects of fusion casting and extremely high requirements for internal metallurgical quality, most of the main internal requirements mainly rely on imports, mainly the manufacture of large aircraft parts and connectors. As a result, the world's aircraft manufacturing industry is developing in the direction of large-scale development, and the demand for 7A85 hard aluminum alloy materials is also increasing day by day.

7A85 aluminum alloy plate has high specific strength, specific rigidity and good processing performance, and has better corrosion resistance and higher substitution. It is widely used in aerospace and civil industry. Aluminum Corporation of China successfully cast 7A85 duralumin alloy slab and 7A85 duralumin alloy round ingot. The successful casting of 7A85 hard alloy slabs and round ingots marked the further improvement of China Aluminum’s manufacturing technology and scientific research and innovation capabilities, and enhanced China Aluminum’s influence in the field of hard aluminum alloy manufacturing. The development of aluminum alloy is of great significance.

The successful manufacturing of 7A85 aluminum alloy will further break through the situation that core materials rely on imports for advanced aircraft manufacturing. As a professional manufacturer of cemented carbide materials, Chinalco has been committed to the development and manufacturing of aluminum alloy materials for aerospace use. Contribute to the development of pilots’ aerospace industry. Specs of

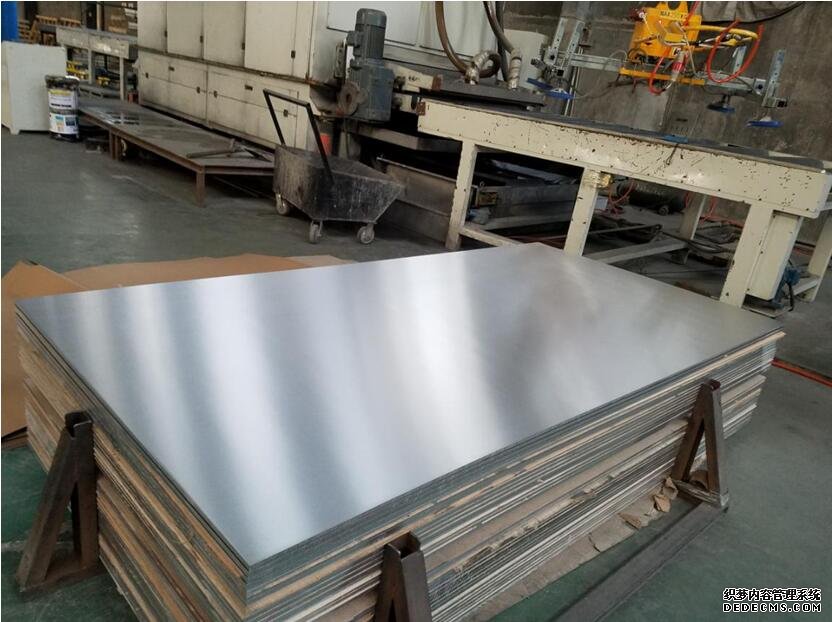

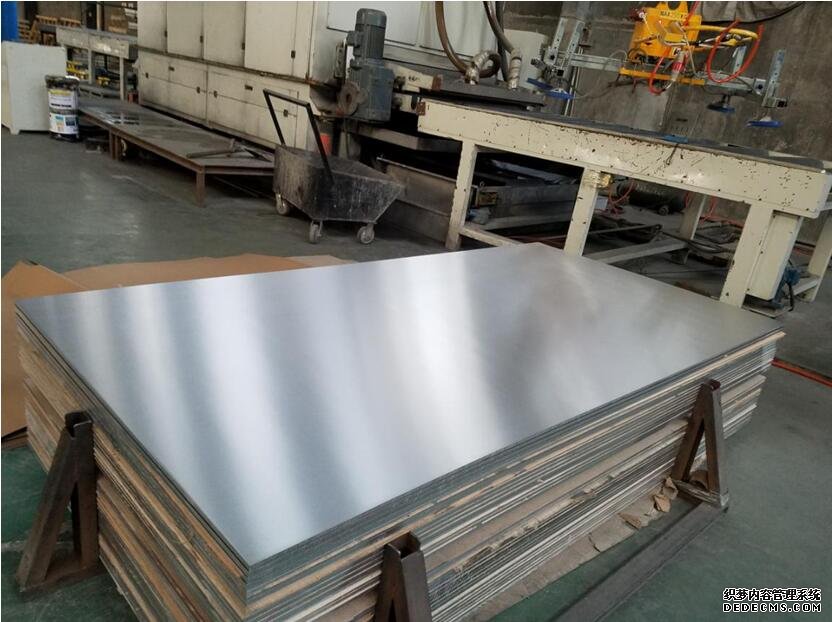

7A85 aluminum alloy plate

Alloy: 7A85

Temper: T7651, T7452

Thickness: 4--260mm

Width: 1200--3800mm

Mechanical property:

|

Alloy |

Temper |

Thickness (mm) |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation A50% |

Standard |

|

2A12 |

T7651

LT Direction |

100--178 |

530--550 |

490--510 |

8.5--12.5 |

AMS4329 |

|

T7452 LT Direction |

120--265 |

520--545 |

485--500 |

10--12.5 |