7075 alloy is an ultra-high strength aluminium alloy which has been applied in aircraft manufacturing. Since 1950s, 7075 alloy and 2024 alloy have become two pillars of aluminum alloy for aerospace structure. Among the common aluminum alloys,

7075 aluminum alloy has the best strength, but it can not be welded, and its corrosion resistance is very poor. Many CNC cutting parts are made of 7075 alloy. Zinc is the main alloy element in this series, with a little magnesium alloy, the material can be heat treated to achieve very high strength characteristics. This series of materials are generally added with a small amount of copper, chromium and other alloys, of which

7075 aluminum alloy is the most superior, with the highest strength, suitable for aircraft frame and high-strength accessories.

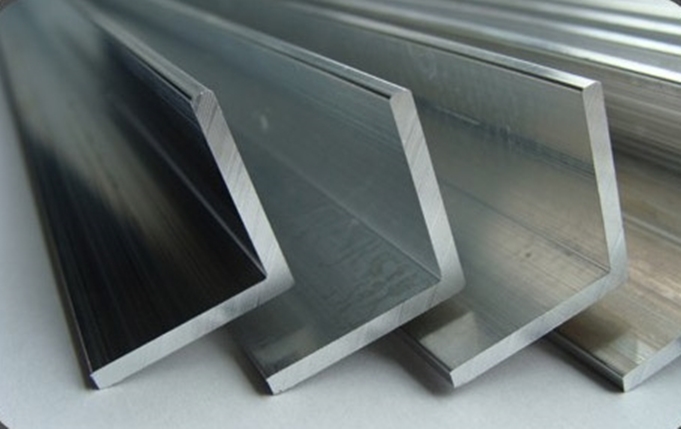

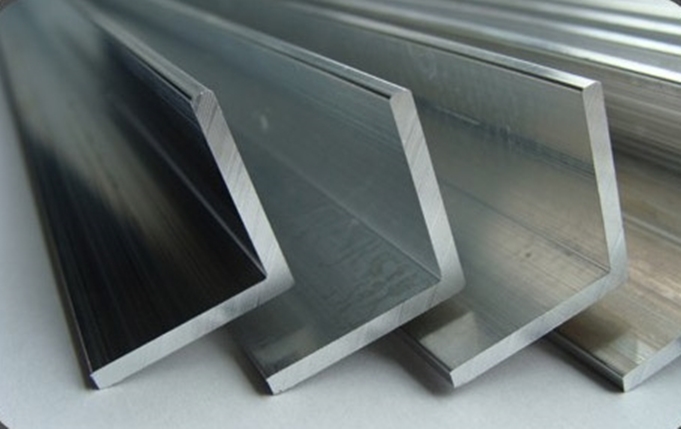

Characteristic of

7075 aluminum angle extrusion:

1. High strength heat-treatable alloys. 2. Good mechanical properties. 3. Good usability. 4. Easy to process and good wear resistance. 5. Good corrosion resistance and oxidation resistance.

Main uses of

7075 aluminum angle extrusion:

Aircraft fixtures, trucks, tower buildings, ships, pipelines and other applications in buildings requiring strength, weldability and corrosion resistance. For example: aircraft parts, gears and shafts, fuse parts, instrument shafts and gears, missile parts JUMP-in valve parts, turbines, keys, aircraft, aviation and national defense applications