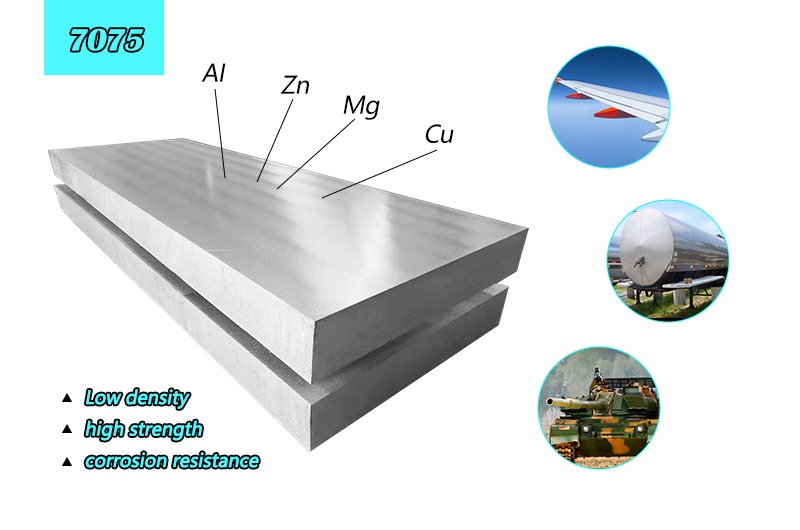

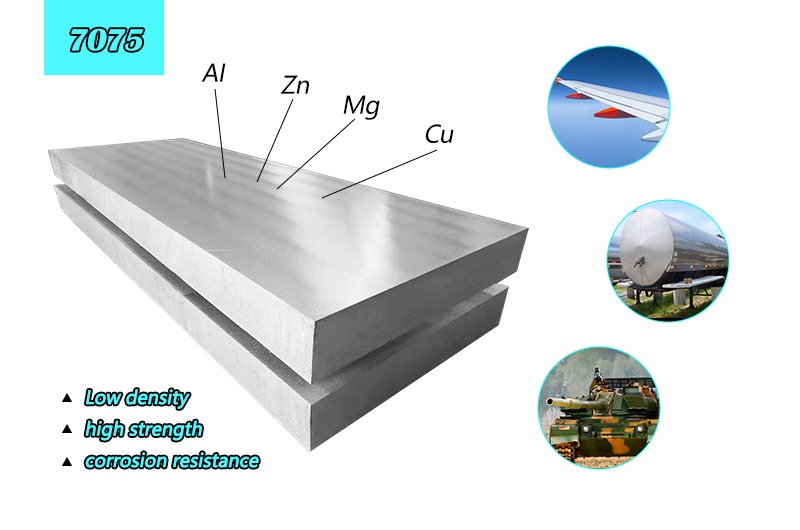

7075 aluminum alloy belongs to Al Zn mg Cu alloy system. It is widely used in modern aerospace industry and some civil transportation industries. It has the advantages of low density, high strength, corrosion resistance and good processability. In recent years, the integration and large-scale of aircraft components require the use of high-performance thick section aluminum alloy materials (such as large forgings and ultra thick plates) to reduce weight, reduce cost and improve reliability.

As a typical heat treatable strengthened aluminum alloy, 7075 aluminum alloy produces components with large thickness. When the thick section materials are quenched after solid solution, it is often difficult for the central layer to obtain a sufficiently high cooling rate, resulting in great differences in internal and external microstructure and properties of forgings. The external surface is cold too fast, and the longitudinal yield strength exceeds the index, Due to insufficient solid solution, the core performance leads to heat treatment repair and even scrap of forgings.

7075-T6 forged aluminum solid solution adopts different quenching water temperatures of 20 ~ 35 ℃ and 60 ~ 85 ℃ to obtain different cooling rates, so as to study the effect of water quenching temperature after solid solution on its aging

Electrical conductivity, microstructure and tensile properties at room temperature.

The effect of quenching water temperature on the mechanical properties of

7075-T6 forged aluminum was studied by means of conductivity test, metallographic structure and room temperature tensile test. The results show that: (1) 7075 material is highly sensitive to water temperature, the cooling speed of quenching affects the internal and external performance differences of forgings, and the performance differences after two-stage aging in the three directions of solution quenching water temperature of 60 ~ 85 ℃ are small, Solution quenching water temperature is 20 ~ 35 ℃, and the difference of high strength after two-stage aging is about 13 ~ 17ksi compared with water temperature of 60 ~ 85 ℃.

(2) the solution quenching water temperature of 7075-t7352 forging is 60 ~ 85 ℃, which is higher than that of 20 ~ 35 ℃. After two-stage aging, the conductivity is increased by 2% IACS. After two-stage aging, the metallographic structure is uniform, and there are certain directionality in three directions.

(3) the effective thickness of 7075-t7352 forging is about 140mm, and the hardenability of solution quenching water temperature of 20 ~ 35 ℃ is about 55mm.