In the 20th century and 1990s, under the requirement of continuing to improve the strength of aluminum alloy, Chalco Aluminum developed 7055 aluminum alloy material from 7150. The strength of 7055 aluminum plate is 10% higher than that of 7150 and 30% higher than that of 7075.

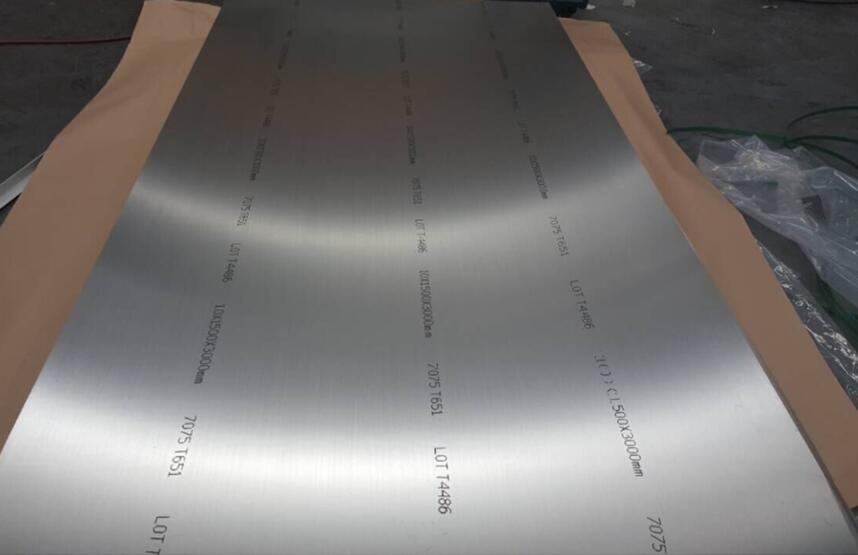

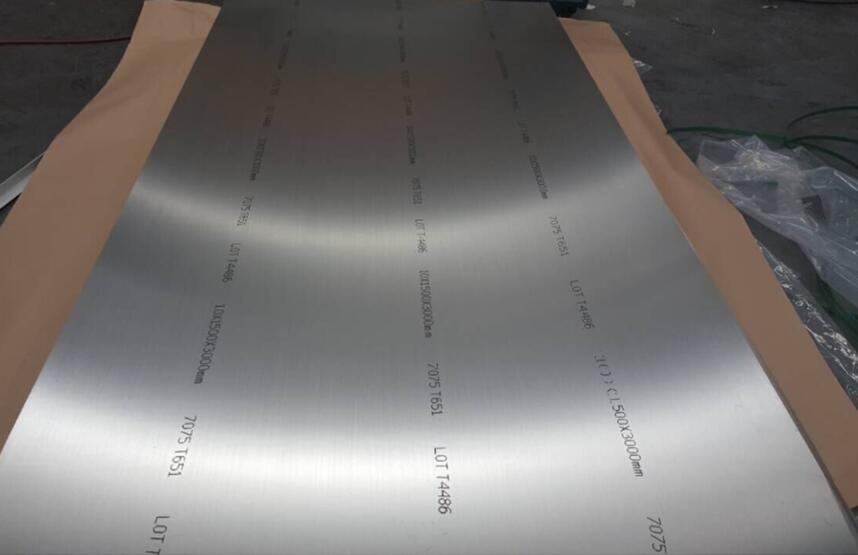

7055 aluminum plate sheet is mainly for customer groups in the high-tech industry chain, such as aluminum used in the aerospace industry, automobile manufacturing and electronics industry. 7055 aluminum plate sheet not only meets high standards, but also meets the special requirements of customers. We make full use of our rich experience and professional skills in the research and development of

7055 aluminum plate sheet, and our products can fully meet the requirements of the aerospace market.

The main alloying element of 7055 series aluminum alloy is zinc. Adding magnesium to the alloy containing 3%-75% zinc can form MgZn2 with significant strengthening effect, making the heat treatment effect of this alloy far better than aluminum-zinc binary alloy. The content of zinc and magnesium in the steel, the tensile hardness will be further improved, but its resistance to stress corrosion and spalling corrosion will be reduced. After heat treatment, it can achieve very high strength characteristics. This series of materials will generally be added Discuss alloys such as copper and chromium. In this series,

7055 aluminum plate sheet is the top grade, which is known as the excellent product among aluminum alloys. It has high strength and far better than mild steel. This alloy has good mechanical properties and anode reaction. Mainly used for Aerospace, mold processing, mechanical equipment. Tooling fixtures, especially for aircraft manufacturing structures and other high-stress structures that require high strength and strong corrosion resistance.