7055 aluminum alloy has the characteristics of high strength and high flexibility and toughness. It is a 7xxx series (Al Zn mg Cu) aluminum alloy with Zn, Mg and Cu as the main strengthening alloy elements. It has the highest Zn content and has the advantages of low density, high strength and good plasticity. It is a widely used high strength and high toughness aluminum alloy at present;

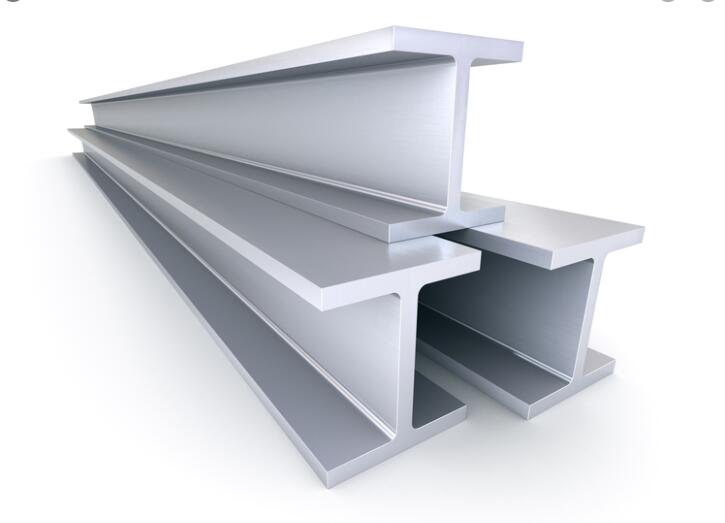

7055 aluminum alloy extrusions has the advantages of fine grain, uniform and dense structure and no macro segregation.

7055 aluminum alloy is the alloy with high strength among deformed aluminum alloys up to now, commonly known as "ace aluminum alloy", and it is also an ultra-high strength aluminum alloy with leading comprehensive performance registered in the United States.

7055 aluminum alloy extrusions replaces traditional aluminum alloy, alloy steel, titanium alloy and other materials in structural parts to reduce weight by 20-60%.

7055-t76 aluminum alloy extrusions adopts the heat treatment process of reverse extrusion and solid solution + over aging. The material can not only ensure the same mechanical properties as T6 state, but also have good stress corrosion resistance. After extrusion + T76 heat treatment, the strength of the material is greatly improved, σ B reaches 670 MPa, reduces the defects such as pores and cold powder easily produced in the process, and ensures good tensile properties.

7055 aluminum alloy sheet extrusions is mainly used in the wing beam, fuselage and other high-strength structural components of large passenger aircraft. It is an indispensable and important material in the aviation industry.