The 7 series aluminum alloy has been the first choice for aerospace and aircraft applications since it was introduced into commercial aircraft manufacturing after World War II. The 7 series provides designers with extremely high strength, low manufacturing cost and low replacement risk. It is the preferred alloy for strength as the main application. 7051-alloy 7050 aluminum sheet is more commonly used in aerospace applications than 7050, especially in the thickness range of 50-150 mm, because it maintains strength in the thicker part. Alloy 7050 aluminum plate has two states. T7651 combines the highest strength, good spalling corrosion resistance and stress corrosion cracking resistance. The

T7451 aluminium plate sheet provides better SCC resistance and excellent peeling resistance at a slightly lower strength level.

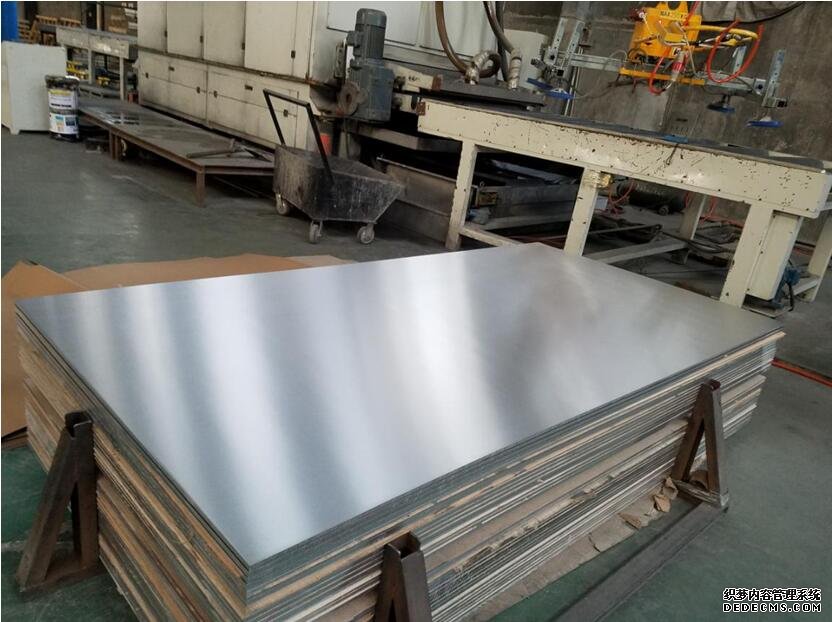

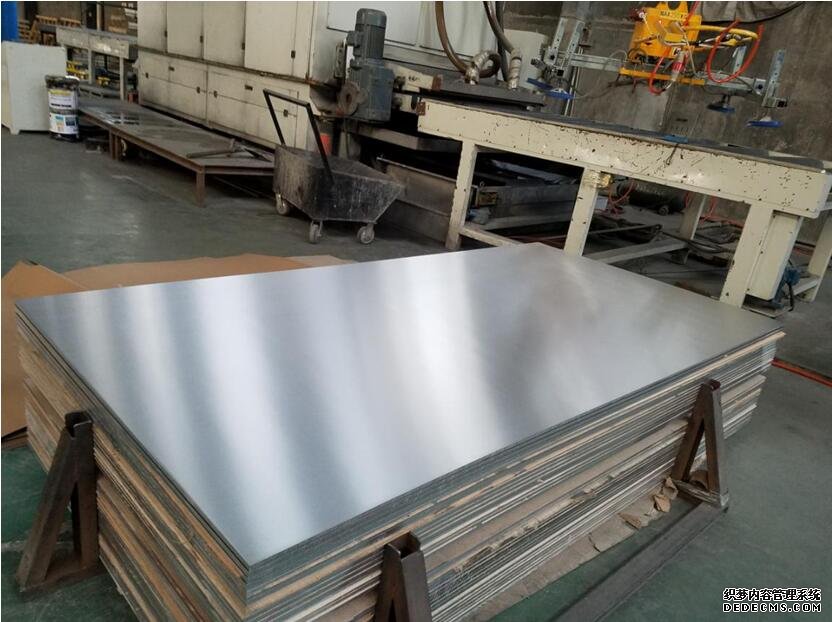

Henan Chalco has a stock of

7050 T7451 aluminium plate sheet and 7050 T7651 aluminum alloy sheet. In addition, it can also provide 7050 T74511 aluminum alloy bar. 7050 T7451 has better toughness, corrosion resistance and stress corrosion cracking resistance than 7050 alloy. Because it has a lower quenching sensitivity than most other aerospace alloys, 7050 retains its strength properties in thicker sections better than other high-strength alloys.

7050-T7451 aluminium plate sheet is an excellent choice for the aerospace and aircraft industry, suitable for making bulkheads, fuselage frames and wing skins.