6×××Series aluminum alloy is an ideal material for manufacturing appearance structural parts of electronic products because of its high strength, good thermal conductivity, machinability and good chemical polishing effect. It is widely used in consumer electronics shells, such as notebook computers, mobile phones, televisions, etc. Among them, 6013 aluminum alloy is one of the most advanced aluminum alloys in the world. Compared with 6061-T6 alloy, 6013-t6 aluminum alloy has about 25% higher strength, even comparable to 7 ××× Strength of aluminum alloy [1-3]. In addition,

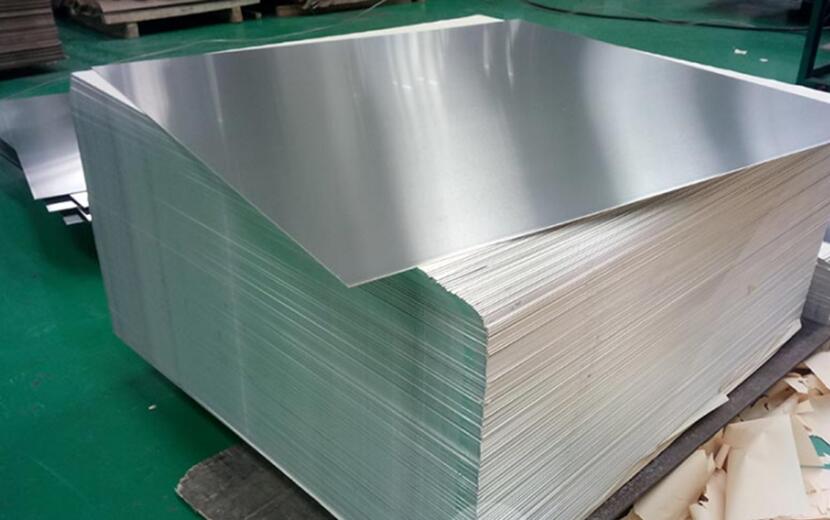

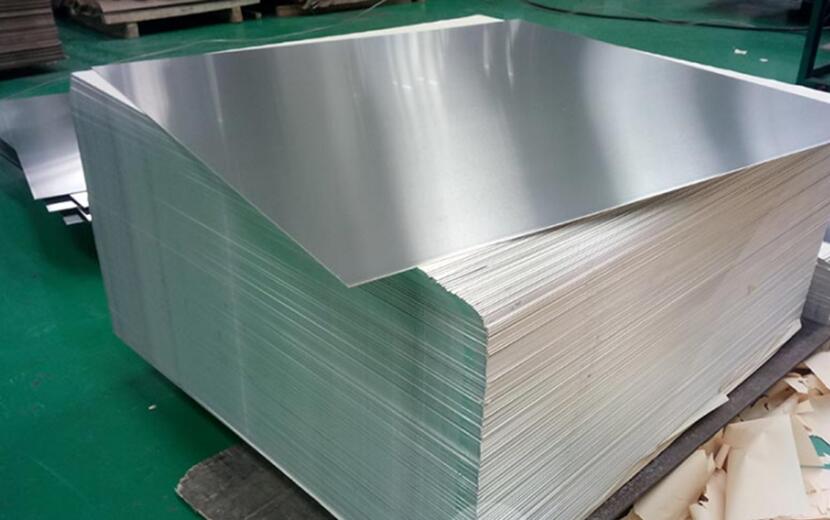

6013 aluminum alloy plate

6013 aluminum alloy plate also has better drilling performance and easy chip removal. It can be used to drill more complex parts and significantly reduce the drilling cost. Therefore, 6013 alloy is regarded as a new generation of ideal material to meet the further needs of the electronic product appearance structure market for high strength, lightweight and easy processing.

Chalco aluminum developed

6013 aluminum alloy plate for electronic appearance to produce 6013 aluminum alloy plate with superior comprehensive performance and good anodizing effect.

1) When the heat treatment system is 570 ℃ / 40 min solid solution + 172 ℃ / 12 h aging, the mechanical properties of the alloy are the best, and the corresponding yield strength, tensile strength and elongation are 330 MPa, 389 MPa and 18.5% respectively.

2) The mechanical properties of the alloy are sensitive to the parking time before aging. When the parking time exceeds 1 D, the mechanical properties decrease significantly. After the parking time is extended to 2 D, the mechanical properties of the alloy remain unchanged.

3) There is a coarse (FeMn) 3sial15 phase in the aged alloy, resulting in obvious segregation of impurity phases such as Fe and Si. However, Cu, Mn and other alloy elements are evenly distributed in the aluminum matrix, and the surface quality of the plate after anodizing is good, which can meet the needs of customers.