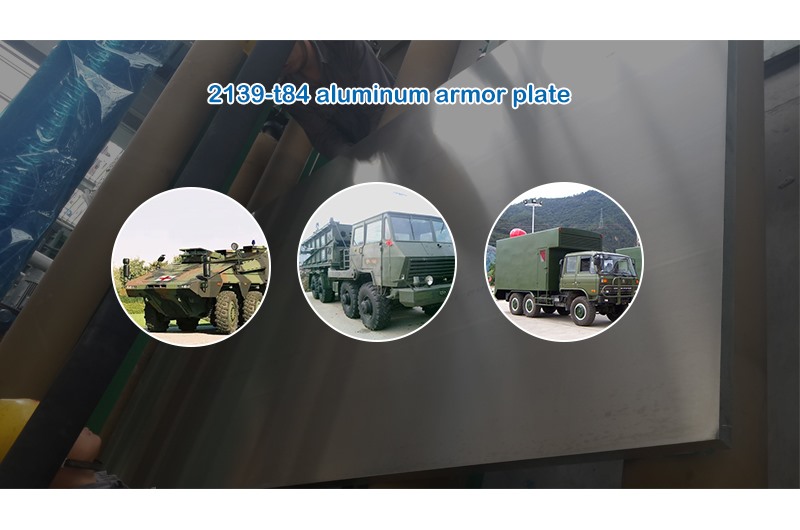

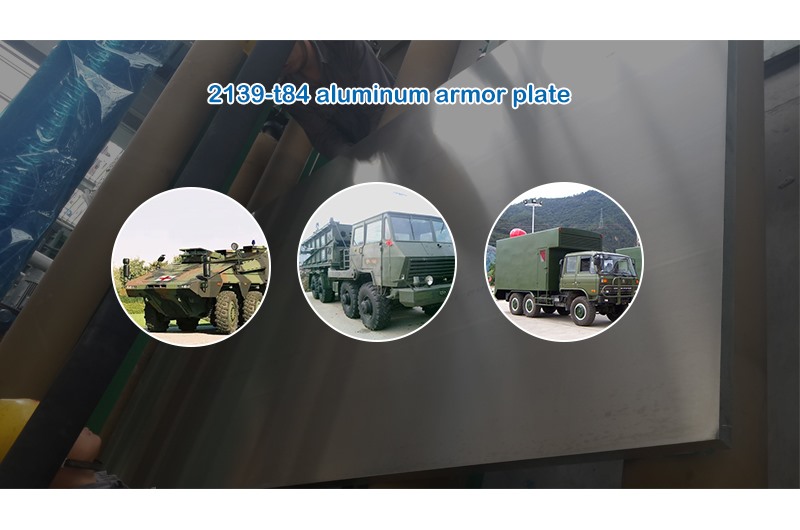

The application of aluminum alloy as armor plate began in the mid-1950s and has been used in wheeled armored vehicles and tracked armored vehicles for more than 60 years. Armored vehicles have played an important role in search and reconnaissance, rescue and infantry transportation. The aluminum alloy armored personnel vehicle is the M113 of the United States. It uses a large amount of aluminum alloy armor. The armor is thick enough not to be broken down by bullets to ensure personnel. At the same time, it is much lighter than the previous steel armored vehicle and can be transported by aircraft.

U.S. Army Research Laboratory (Army Research Laboratory, ARL) has studied the performance and size of armor plate alloy on the side and front of armored vehicle for a long time and a series of simulated live fire. Two kinds of aluminum alloys with good comprehensive performance have been selected. Their strength, anti shrapnel explosion, anti bullet penetration and anti-corrosion have been well combined, and they can be formed through intermediate heat treatment These two alloys are 2139 alloy and 7056 alloy which have been applied in aviation industry.

2139 alloy is a structural alloy developed for the aerospace industry. It has high strength and fracture toughness. It is an aluminum alloy with comprehensive properties. After a series of standardized shooting tests and field tests conducted by the U.S. Army Research Laboratory for a long time, it is considered that it is also a good armor aluminum alloy. In addition to qualified bulletproof performance, it also has good corrosion resistance and heat resistance, It will not soften at high temperature. For armored vehicles, high corrosion resistance is also an important technical index, because it needs to operate and fight in extremely severe and complex environment. It is commendable that the stress corrosion sensitivity of 2139 alloy is very low.

2519-T87 alloy thick plate was used as armor plate early. Later, it was found that it had high stress corrosion cracking sensitivity and was eliminated because it was not suitable for combat under complex conditions. The composition (mass%) of 2139 alloy is as follows: si0.10, fe0.15, Cu (4.5 ~ 5.5), Mn (0.20 ~ 0.60), Mg (0.20 ~ 0.80), cr0.005, zn0.25, ti0.15, v0.05, Ag (0.15 ~ 0.60), other impurities are 0.05 individually, 0.15 in total, and the rest are al.

According to the American military material standard mil-dtl32341a, 2139 alloy has low mechanical properties. According to the composition of 2139 alloy, it is an alloy with low impurity content, so it has high fracture toughness, fatigue resistance and damage resistance.

2139 alloy thick plate has two states: AP / FSP (U.S. patent / Federal Patent) anti shooting grade, i.e. T8 state. The production process of the former state is artificial aging after appropriate cold working rate, i.e. cold working after solution treatment and artificial aging, so that it has good comprehensive performance and can be used to manufacture the side deck and top deck of armored vehicles; the production process of T81 state thick plate is solid solution After treatment, after about 1% cold working deformation, the strength is slightly improved, and then artificial aging is carried out. The armored vehicle made of 2139-t81 alloy thick plate has stronger protection performance, that is, when the protection performance of the armored vehicle is improved, the 2139-t81 alloy armored vehicle is much lighter, more flexible and faster.

The research of the U.S. Army Research Laboratory shows that when the thickness of armor plate is equal, 2139 alloy plate can resist 2110ft / s bullet shooting, while the shooting speeds of 5083-h131 alloy plate and 7039-t64 alloy plate are 1780ft / s and 1910ft / s respectively.

The explosion resistance of 2139 alloy is generally better than that of traditional alloy, especially 2139-t84 alloy, because T84 plate has higher tensile strength and fracture toughness, and they are well combined. In the standardized bursting test, its plastic deformation is much smaller than that of 5083-h131 alloy thick plate. The deformation of

2139-t84 aluminum armor plate is about 50% less than that of 5083-h131 alloy. Therefore, in case of explosion on the battlefield, the impact of 2139-t84 alloy armored vehicle will be reduced, which can greatly reduce potential damage.

Anti explosion state board (T84) it is usually used as the lower deck of armored vehicles. The plates are artificially aged, and the aging temperature is quite high, so it has formability.

2139-t84 aluminum armor plate also needs to undergo intermediate solid solution treatment protected by patent. This kind of plate has both high strength and good formability. The stress in the formed parts is low, which is very favorable for future processing and forming.