Aluminum alloy has the advantages of low density (only one third of the density of iron), good plasticity, high strength, small specific gravity, easy forming, corrosion resistance and low cost. It can be made into various profiles and plates. In order to meet the needs of large-scale, multi load and high-speed development of aircraft, the aluminum alloy industry has prepared a series of aerospace structural materials with excellent properties by adding trace elements, changing the chemical composition of the alloy, improving the purity of the alloy, improving the casting quality and processing technology, optimizing the heat treatment process and other means, Among them, 2024 aluminum alloy is the leader. 2024 aluminum alloy is a high-strength structural material with excellent comprehensive properties because of its light weight, high strength, good heat resistance and fatigue properties and low processing cost. 2024 aluminum alloy is one of the most widely used aviation aluminum alloys at present. It is widely used in the fuselage frame, wing beam, fuselage skin, partition frame of civil aircraft such as Boeing, Airbus and C919, as well as the structural parts that need to bear high cyclic load on various aircraft.

2024 T3 aluminum sheet

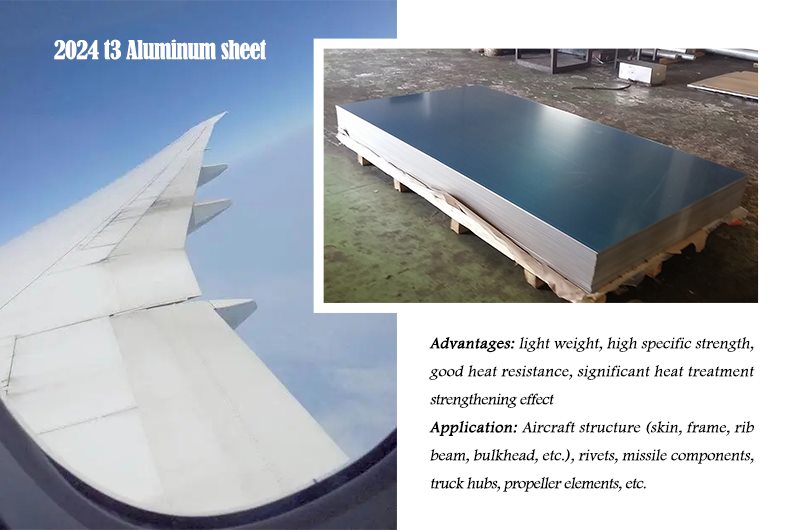

2024 T3 aluminum sheet has been widely used in the field of aerospace because of its excellent properties such as light weight, high specific strength and good heat resistance.

The strength of

2024 T3 aluminum sheet is higher than that of 7075 alloy. The formability is better in thermal state, annealing and new quenching state, and the strengthening effect of heat treatment is remarkable, but the requirements of heat treatment process are strict. Poor corrosion resistance, but it can be effectively protected by coating with pure aluminum; Cracks are easy to occur during welding, but special processes can be used for welding or riveting. It is widely used in aircraft structures, rivets, truck hubs, propeller components and other structural parts.

2024 T3 aluminum sheet is widely used in aircraft structures (skin, skeleton, rib beam, spacer frame, etc.), rivets, missile components, truck hubs, propeller components and other structural components.