E-mail:

sales@chalcoaluminum.com

E-mail:

sales@chalcoaluminum.com

Email: sales@chalcoaluminum.com

Mobile:86 17344894490

7A09 Aluminum Alloy Sheet Round Bar Profile Forgings

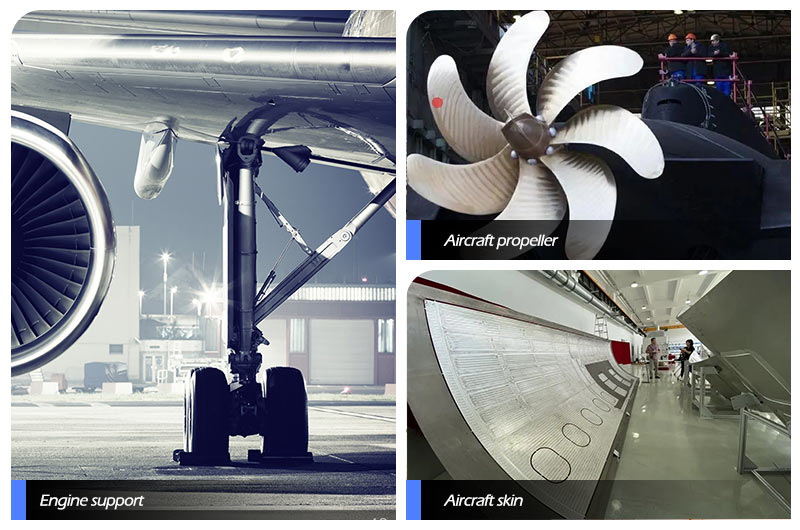

Ultra high strength Aluminum Alloy 7A09 alloy is Al-Zn-Mg-Cu, the strength of 7A09-T6 alloy is the highest, the aviation industry with one of the highest strength Aluminum Alloy deformation, the composition ratio of 7A04 alloy more superior performance, so it has better, get more extensive application in aircraft manufacturing, used in the manufacture of various important components of the force,7A09 aluminum alloy sheet round bar forgings have been widely used in aircraft, transport aircraft, and medium bomber trainer, for the production of the front landing gear, wing, fuselage connection frame, beam, pillar, partitions, floors, main beam joints and tail on the wall, the working cylinder hydraulic system, hydraulic oil tank of the movable rod inside and outside the tube, and other key components. Because of its high strength, the weight reduction effect is good and the safety of the aircraft is improved.

7A09 aluminum alloy is a high -strength aluminum alloy, which is mainly composed of aluminum, zinc, magnesium and copper. This alloy has the characteristics of good mechanical properties, corrosion resistance and weldability, and is one of the commonly used materials in the fields of aerospace, weapons and equipment.

Chalco can produce 7A09 aluminum alloy in ASTM B209, ASTM B210, ASTM B308, ASTM B241, GB/T 3190-2010, GB/T 3880.1-2012. It can meet parameters such as chemical composition, physical performance, size deviation, and surface treatment required by standard requirements.

The semi-finished products of 7A09 alloy are 7A09 aluminum alloy sheet round bar forgings.The alloy has satisfactory fracture toughness in T6 state. The strength and yield strength in T73 over aging state are lower than that in T6 state, but the alloy has excellent stress corrosion resistance and high fracture toughness. The T6 state material has good resistance to exfoliation and corrosion. When the temperature rises, the strength of the alloy decreases, and the long-term use temperature should not exceed 125 ℃.

| Chemical Composition of 7A09 alloy | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Others | Al | |

| Each | Total | ||||||||||||

| 7A09 | 0.50 | 0.50 | 1.2~2.0 | 0.15 | 2.0~3.0 | 0.16~0.30 | - | 5.1~6.1 | 0.10 | - | 0.05 | 0.15 | Remainder |

| Alloy | Alloy series | Main features | σb Value/MPa | Working Temperature/℃ |

| 7A09 | 7075(American) |

At present,7A09 aluminum alloy sheet round bar forgings is one of the most powerful domestic aluminum alloys, which can produce various specifications of plate, bar, profile, thick pipe fittings and forgings. There are four heat treatment states of T6, T73, T76 and T74. The chemical composition is better than that of 7A04 alloy, and its comprehensive properties are better. Under the condition of annealing or solid solution heat treatment, it has good forming properties at normal temperature. The forming performance is lower in the solid solution heat treatment and artificial aging condition, but with the increase of temperature, the forming properties are improved. Resistance welding can be carried out, and it is not suitable for welding. |

455~540 |

<125 |

| Physical Property of 7A09 Alloy | |||||||||

| Alloy | Type | Temper | δ Size /mm | σb/MPa | σp 0.2/MPa | δ % | KIC or KC | Standard | |

| 7A09 |

Aluminum sheet |

T6 | 1.0~2.5 | LT:480 | LT: 410 | LT:7 | - | GJB 2053-1994 | |

| >2.5~6.5 | LT:490 | LT: 420 | LT:7 | ||||||

| T9 | 2.0~4.0 | LT:520 | LT: 460 | LT:6 | |||||

| T62 | 1.0~2.5 | LT:470 | LT: 400 | LT:7 | |||||

| >2.5~6.5 | LT:480 | LT: 410 | LT:7 | ||||||

| Aluminum plate | T6 | 7~10 | LT:490 | LT: 420 | LT:7 | - | GJB 2662--1996 | ||

| T62 | 7~10 | LT:480 | LT: 410 | LT:7 | |||||

| H112--T6 | 7~10 | LT:490 | LT: 410 | LT:6 | |||||

| >10~25 | LT:490 | LT: 410 | LT:4 | ||||||

| >25~40 | LT:490 | LT: 410 | LT:3 | ||||||

| T6 | 35~40 | ST 390 | - | 2 | |||||

| Pre-streching aluminum plate | BCSYU | >1.0~6.0 | LT:540 | LT:460 | LT:9 | - | GJB 1741--1993 | ||

| >6.0~10.5 | LT:540 | LT:470 | LT:7 | ||||||

| Extuded aluminum bar | T6 | 5~22 | L:490 | L:370 | L:7 | - | GJB 2054---1994 | ||

| >22~150 | L:530 | L:400 | L:6 | ||||||

| H112---T6 | >150~250 | L:500 | L:400 | L:4 | |||||

| High strength aluminum bar | H112---T6 | 20~100 | L:550 | L:450 | L:6 | ||||

| >100~150 | L:530 | L:430 | L:6 | ||||||

| T6 | 20~150 | L:550 | L:450 | L:6 | |||||

| Extruded aluminum bar | T73 | ≤38 | L:485 | L:420 | L:7 | - |

Q/6S 824--1997 Q/S 321--1991 |

||

| >38~76 | L:475 | L:410 | L:7 | ||||||

| >76~125 | L:470 | L:395 | L:6 | ||||||

| T74 | ≤22 | L:490 | L:375 | L:7 |

Q/6S 1352--1997 Q/S 320--1991 |

||||

| >22~160 | L:530 | L:405 | L:6 | ||||||

| >160 | L:510 | L:405 | L:5 | ||||||

| Extruded aluminum profile | T6 | ≤10.0 | L:500 | L:440 | L:6 | GJB 2507--1995 | |||

| >10.0 | L:540 | L:460 | L:6 | ||||||

| T74 | ≤10.0 | L:500 | L:440 | L:6 | - | Q/6S 1490--1999 | |||

| Extruded aluminum tube | T6 | 25~120 | L:530 | L:400 | L:6 | - | GJB 2381--1995 | ||

| >120~250 | L:510 | L:400 | L:5 | ||||||

| Die forgings | T6 | - | L:530 | L:400 | L:6 | ||||

| LT:450 | - | LT:4 | |||||||

| ST:425 | - | ST:3 | |||||||

| Free forgings | T6 | - | L:510 | L:420 | L:6 | ||||

| LT:440 | - | LT:3 | |||||||

| ST:420 | - | ST:2 | |||||||

| Die forgings | T73 | - | L:455 | L:385 | L:7 |

GJB 1057--1990 GJB 2351--1995 |

|||

| LT:440 | LT:370 | LT:4 | |||||||

| ST:425 | - | ST:3 | |||||||

| Fee forgings | T73 | - | L:455 | L:385 | L:6 | ||||

| LT:440 | LT:370 | LT:4 | |||||||

| ST:420 | - | ST:2 | |||||||

| Die forgings | T74 |

weight≤30kg |

L:510 | L:430 | L:6 | GJB 2351--1995 | |||

| LT:450 | - | LT:4 | |||||||

| ST:425 | - | ST:3 | |||||||

|

weight>30kg |

L:510 | L:430 | L:6 | ||||||

| LT:450 | - | LT:4 | |||||||

| ST:425 | - | ST:2 | |||||||

| Die forgings |

T74 |

weight≤30kg |

L:490 | L:410 | L:6 | ||||

| LT:440 | - | LT:3 | |||||||

| ST:420 | - | ST:2 | |||||||

|

weight>30kg |

L:490 | L:410 | L:5 | ||||||

| LT:440 | - | LT:3 | |||||||

| ST:420 | - | ST:2 | |||||||

| Alloy | Temper | Aircraft models | Application parts and typical parts |

| 7A09 |

Aluminum sheet: T6,T9,T62 Aluminum plate:T6, T62 Aluminum profile: T6,T74 Aluminum forgings:T6,T74,T73 |

,Z9, Z10,Z11 etc., |

All kinds of beams, frames, baffles, panels, ribs, joints, skins, front landing gear, actuating cylinder, arm, pillar and so on. |

High -strength: 7A09 Aerospace aluminum plate has extremely high tensile strength and yield strength, which can reach 550MPa and 495MPa, which is more advantageous than ordinary aluminum alloy materials. Therefore, the 7A09 aviation aluminum rod is widely used in the manufacture of high -intensity aerospace components, military equipment, sports equipment and other fields.

Significant hardness: 7A09 Aerospace aluminum forged still maintains high hardness under high temperature conditions, and has excellent fatigue strength, which can effectively extend the service life of the material.

Good processing: 7A09 Aerospace aluminum rod has a good processing performance. It can be processed with a variety of processing processes, such as squeezing, stretching, and stamping. At the same time, the welding performance of the 7A09 aviation aluminum rod is also good, and multiple welding methods can be used to connect.

Strong corrosion resistance: 7A09 Aerospace aluminum tube has good corrosion resistance, can resist corrosion factors such as oxidation and vulcanization, and make it still have a longer service life in harsh environments.

Lightweight: The density of 7A09 Aerospace aluminum alloy is low, nearly 3 times lighter than ordinary steel. Therefore, the use of 7A09 aviation aluminum can greatly reduce the weight of the entire aircraft and improve its performance and efficiency.

In short, 7A09 Aerospace Aluminum alloy has the advantages of high strength, significant hardness, good processing, strong corrosion resistance and lightweight. Equipment and other fields. It should be noted that the price of 7A09 aluminum alloy is relatively high and it is difficult to process, so it is necessary to consider it according to the specific situation when using it.

7A09 Aerospace aluminum plate: 7A09 aluminum plates are usually used to manufacture the shells, wings, rear wings and other structural parts of the aircraft, as well as components such as missiles, satellites, rockets.

7A09 Aerospace Aluminum round bar: 7A09 Aluminum round bar is widely used in the structural parts, connectors, shafts, rods, landing gear, and aircraft abdomen of the manufacturing aircraft and other aircraft.

7A09 Aerospace aluminum forged: 7A09 aluminum forging parts are widely used in manufacturing turbine fan, high pressure compressor, aviation engine parts, connecting parts, structural components, etc.

7A09 Aerospace aluminum profile: 7A09 aluminum profiles are usually used to manufacture the structural parts of the aircraft, such as fuselage, wings, rear, flap, landing gear and other components.

7A09 Aerospace Aluminum Tube: 7A09 aluminum pipes are usually used to manufacture aircraft structural parts, such as fuel tanks, fuel pipes, hydraulic system pipes and other components.

In addition to the products listed above, 7A09 aluminum alloy can also be made into aluminum foil, aluminum lines, etc. The specific usage depends on different application needs.

Henan Chalco provides excellent quality of aerospace materials and high -quality technical services in the market, and has deep knowledge of how to support customers in responding to future challenges.

We have a whole set of advanced domestic aerospace materials research and development, testing, and analysis instruments to provide guarantees for the efficiency of new product research and development and accelerate the transformation of scientific and technological achievements. In addition, our R & D & innovation and verification capabilities can help enhance the competitiveness of customers by saving the time and costs of new product development and marketing.

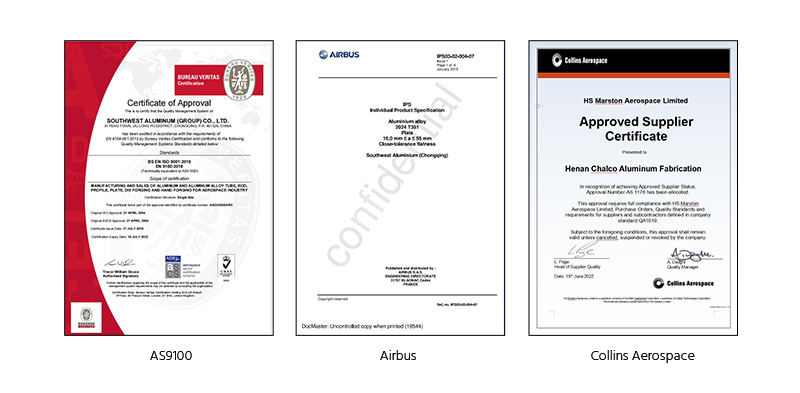

We have passed the AS9100 certification required by the aviation industry and the Collin Aviation Certification. According to the AMS QQ-A-225/9 standard required by customers, it is required to provide a strong guarantee for the quality of aerospace materials produced by our company.