E-mail:

sales@chalcoaluminum.com

E-mail:

sales@chalcoaluminum.com

Email: sales@chalcoaluminum.com

Mobile:86 17344894490

7A04 Aluminum Alloy Sheet Plate Rod Profile Forgings

7A04 aluminum alloy sheet plate rod profile forgings is a heat treatment and strengthening alloy of Al-Zn-Mg-Cu system. Its strength is higher than that of hard aluminum. It is characterized by its yield strength close to tensile strength and plasticity, and its sensitivity to stress concentration is strong, especially when subjected to vibration load and repeated static load. Therefore, the design of parts, the manufacturing process and the assembly process need to strictly avoid the stress concentration and the formation of additional stress. The heat resistance of the alloy is poor, and it will soften rapidly when the temperature is higher than 125, and the stress corrosion resistance of thick and thick parts is poor in short and transverse.

7A04 aluminum alloy is a high -strength aluminum alloy, which consists of aluminum, zinc, magnesium, copper and other elements. It has excellent mechanical properties, especially under high temperature conditions with good creep resistance and anti -fatigue crack expansion performance, so it is widely used in aviation, aerospace, military and automobiles.

Chalco can produce 7A04 aluminum alloy that conforms to the UNS A97A04 QQA, 200/2 7A047A04, GB/T 3880.1-2012, ASTM B209-14 standard. It can meet parameters such as chemical composition, physical performance, size deviation, and surface treatment required by standard requirements.

| Chemical composition of 7A04 alloy | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Others | Al | |

| Each | Total | ||||||||||||

| 7A04 | 0.50 | 0.50 | 1.4~2.0 | 0.20~0.60 | 1.8~2.8 | 0.15~0.25 | - | 5.0~7.0 | - | - | 0.05 | 0.15 | Remainder |

| Alloy | Alloy series | Mean features | σb Value/MPa | Working temperature/℃ |

| 7A04 | B95(Russia) | The yield strength to tensile strength, low ductility, sensitivity to stress concentration effects, especially the repeated static load under vibration load and the situation is more obvious, therefore need to strictly avoid stress concentration factor and the formation of additional stress in parts of the design, manufacture and assembly process. The short transverse stress corrosion resistance of the thick and large parts of the alloy is poor. There are mainly plate and extrusion parts. |

480~570 |

<125 |

| Physical Property of 7A04 Aluminum alloy sheet plate profile forgings | |||||||||

| Alloy | Type | Temper | δ size/mm | Directionaerospace aluminum | σb/MPa | σp 0.2/MPa | δ % | Standard | |

| 7A04 |

Aluminum Plate |

T6 | 1.0~2.5 | LT | 480 | 410 | 7 | GJB 2053-1994 | |

| >2.5 | LT | 490 | 420 | 7 | |||||

| T9 | 2.0~4.0 | LT | 520 | 450 | 7 | ||||

| T6 | 7.0~10.0 | L | 490 | 410 | 6 | GJB 2662-1996 | |||

| >10~25 | L | 490 | 410 | 4 | |||||

| >25~40 | L | 490 | 410 | 3 | |||||

| Extruded aluminum profile | T6 | 7.0~10.0 | L | 490 | 370 | 7 | GJB 2054-1994 | ||

| >10~25 | L | 530 | 400 | 6 | |||||

| Extruded aluminum profile | T6 | ≤10 | L | 510 | 460 | 6 | GJB 2057-1995 | ||

| >10~20 | L | 530 | 460 | 6 | |||||

| >20~40 | L | 560 | 460 | 6 | |||||

| >40 | L | 570 | 490 | 6 | |||||

| Free forgings | T6 | Weight≤30KG | L | 510 | 420 | 6 | GJB 2351-1995 | ||

| Weight>30KG | L | 510 | 420 | 5 | |||||

| Die forgings | T6 | Weight≤30KG | L | 530 | 440 | 6 | |||

| Weight>30KG | L | 430 | 440 | 6 | |||||

| Alloy | Temper | Aircraft type | Application parts and typical parts |

| 7A04 |

Aluminum plate: T6,T9 Aluminum forgings:T6 Aluminum profile: T6 |

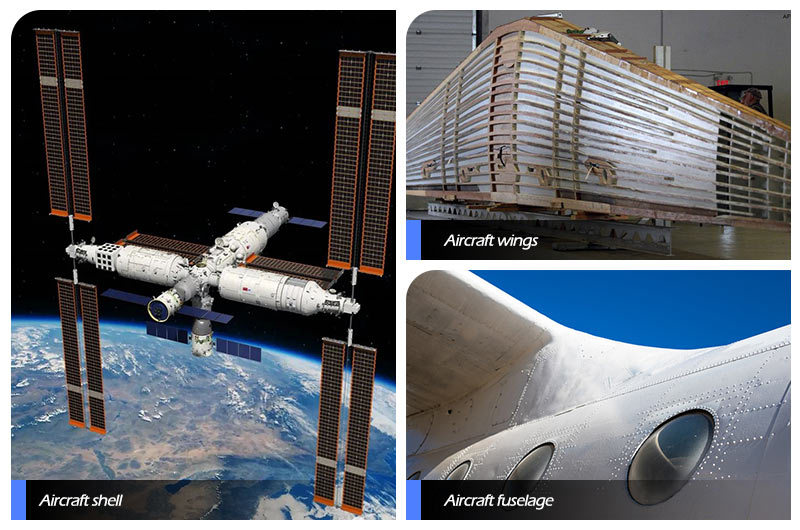

Y8, Y12 | Skin, wall board, all kinds of beams (backlog, forgings), frame, fin, long truss, joint, landing gear and so on. |

High-strength: The strength of 7A04 aluminum alloy is 30-40%higher than that of ordinary aluminum alloy, and it still maintains good strength under high temperature conditions.

Good processing performance: 7A04 aluminum alloy has good plasticity and processability, and can be processed and processed with a variety of molding processes, such as squeezing, forging, stretching, etc.

Good welding performance: 7A04 aluminum alloy can be welded with various conventional welding methods, such as arc welding, TIG welding, mig welding, etc. The intensity and sealability of the weld are better.

7A04 aluminum plate strip: 7A04 aluminum plate can be made into different thickness plates or belt materials for manufacturing aerospaces, automobiles, railway vehicles and large machinery and equipment.

7A04 aluminum profile/aluminum pipe: 7A04 aluminum alloy profiles and aluminum pipes are usually used to manufacture aircraft, high -speed trains and ships, frames of cars and motorcycles, and frames and supporting parts of various mechanical equipment.

7A04 aluminum rod: 7A04 aluminum alloy can be used in the production of forging and extrusion parts, and is used in aviation, aerospace, weapons, transportation, and machinery and equipment.

Other products: 7A04 aluminum alloy can also produce 7A04 aluminum foil, 7A04 aluminum line and other products for manufacturing various aluminum products.

The main products of 7A04 aluminum alloy aluminum board rod profile forging parts are widely used in aircraft structures, such as beams and longitudinal beams, cabinet, wing ribs, skin, joints, landing frame components, etc. It can produce semi -finished products, band materials, profiles and other semi -finished products, rod materials, wall materials, pipes, wire materials, free forging and mold forging parts.

Henan Chalco provides excellent quality of aerospace materials and high -quality technical services in the market, and has deep knowledge of how to support customers in responding to future challenges.

We have a whole set of advanced domestic aerospace materials research and development, testing, and analysis instruments to provide guarantees for the efficiency of new product research and development and accelerate the transformation of scientific and technological achievements. In addition, our R & D & innovation and verification capabilities can help enhance the competitiveness of customers by saving the time and costs of new product development and marketing.

We have passed the AS9100 certification required by the aviation industry and the Collin Aviation Certification. According to the AMS QQ-A-225/9 standard required by customers, it is required to provide a strong guarantee for the quality of aerospace materials produced by our company.