E-mail:

sales@chalcoaluminum.com

E-mail:

sales@chalcoaluminum.com

Email: sales@chalcoaluminum.com

Mobile:86 17344894490

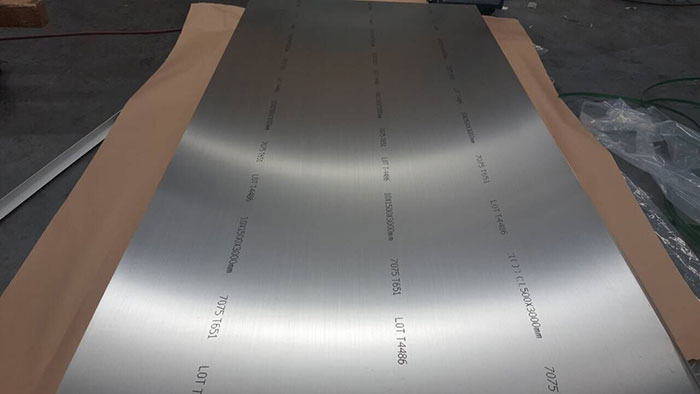

7055 Aluminum alloy sheet profile

| Chemical Composition of 7050 | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Others | Al | |

| Each | Total | ||||||||||||

| 7055 | 0.10 | 0.15 | 2.0~2.6 | 0.05 | 1.8~2.3 | 0.04 | ~ | 7.6~8.4 | 0.06 | 0.05~0.25 | 0.05 | 0.15 | Remainder |

| Alloy | Alloy Series | Main Features | σb Value/MPa | Work Temperature/℃ |

| 7055 | 7050 series | The 7055 Aluminum alloy sheet profile is the 7 * * * * system aluminum alloy with the highest alloying degree at present. The main types are T7751 thick plate and T77511 extrusion parts. Compared with the 7150 alloy, it improves the tensile and compressive strength while maintaining some important properties, such as fracture toughness, corrosion resistance and so on. | 643~669 |

<125 |

| Physical Properties of 7050 Alloy | ||||||||

| Alloy | Type | Temper | Size/mm | Direction | σb/MPa | σp 0.2/MPa | ||

| A | B | A | B | |||||

| 7055 | Aluminum sheet | T7751 | δ12.7~38.1 | L | 614.1 | 627.9 | 593.4 | 607.2 |

| LT | 614.1 | 627.9 | 586.5 | 600.3 | ||||

|

Aluminum profile |

T74511 | δ≤6.325 | L | 572.7 | 579.6 | 524.4 | 538.2 | |

| LT | 538.2 | 545.1 | 496.8 | 510.6 | ||||

| δ6.35~12.675 | L | 579.6 | 586.5 | 531.3 | 545.1 | |||

| LT | 545.1 | 552.0 | 503.7 | 517.5 | ||||

| δ12.7~76.2 | L | 586.5 | 600.3 | 538.2 | 552.0 | |||

| LT | 552.0 | 565.8 | 510.6 | 524.4 | ||||

| T76511 | δ≤6.325 | L | 614.1 | 627.9 | 586.5 | 600.3 | ||

| LT | 572.7 | 586.5 | 545.1 | 558.9 | ||||

| δ6.35~12.675 | L | 621.0 | 648.6 | 586.5 | 627.9 | |||

| LT | 579.6 | 600.3 | 545.1 | 586.5 | ||||

| T77511 | δ12.7~38.1 | L | 648.6 | 655.5 | 621.0 | 641.7 | ||

| LT | 607.2 | 621.0 | 579.6 | 607.2 | ||||

| Alloy | Temper | Aircraft models | Application parts and typical parts |

| 7055 |

Aluminum sheet: T7751 Aluminum profile: T74511、T76511、T77511 |

F-35,B777,ARJ21 | All kinds of components, such as the upper wing structure, horizontal fin, joist beam, seat guide rail and freight slide, are required for high compressive strength and good corrosion resistance. |