E-mail:

sales@chalcoaluminum.com

E-mail:

sales@chalcoaluminum.com

Email: sales@chalcoaluminum.com

Mobile:86 17344894490

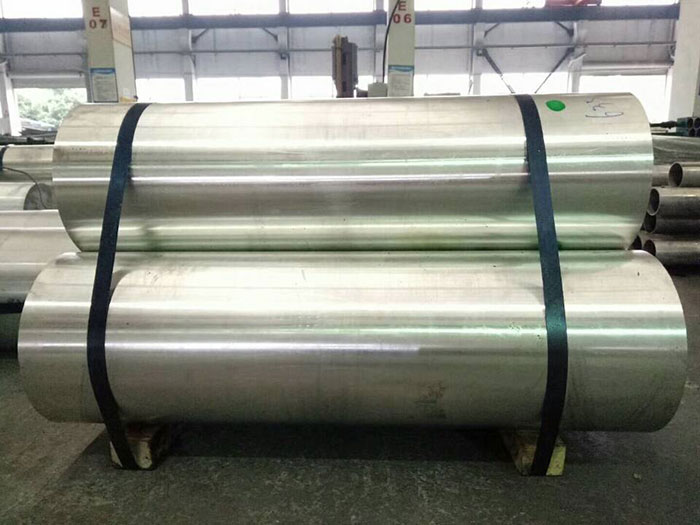

7175 T66 T74 T7452 aluminum alloy forgings

| Alloy | Alloy sereis | Main features | σb Value/MPa | Work Temperature/℃ |

| 7175 | 7075 series | 7175 alloy is specially used to produce forgings and rolling rings, and the state of the material is T74. The characteristic of 7175 T74 aluminum alloy forgings is the special processing and heat treatment process, so that its strength is close to 7075 T6 alloy forgings, and the stress corrosion resistance is close to the 7075 T73 forgings with the best corrosion state. The reduction of Fe and Si rolling can not only improve the forging performance of the alloy, but also improve the stress corrosion resistance and fracture toughness of the forgings. |

595 |

<125 |

| Chemical Composition of 7075 Alloy | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Others | Al | |

| Each | Total | ||||||||||||

| 7175 | 0.15 | 0.20 | 1.2~2.0 | 0.1 | 2.1~2.9 | 0.18~0.28 | ~ | 5.1~6.1 | 0.10 | ~ | 0.05 | 0.15 | Remainder |

| Technical specifications for 7075 T74 aluminum alloy forgings | |||||

| Test Direction | Rm/MPa | Rp0.2/MPa | A5/% | KIC/(N.mm-2).m1/2 | Electrical Conductivity/(MS.m-1) |

| Longitudinal | 490 | 420 | 9 | 33.0 | 22.6 |

| Long Horizontal | 483 | 400 | 5 | 27.5 | |

| Short Horizontal | 469 | 393 | 4 | 23.1 | |

| Demarcation mechanical properties of 7175 T74 alloy rolling forging ring (YS/T 478) | ||||

| Test Direction | Thickness/mm | Tension strength Rm/MPa | Yield Strength Rp0.2/MPa | Elongation A5/% |

| L | <80 | ≥505 | ≥435 | ≥8 |

| Alloy | Temper | Aircraft models | Application parts and typical parts |

| 7175 |

Aluminum forgings: T74 |

A320、Z10、EC120 etc. | Front edge, window frame, fairing joint, manipulating parts, etc. |